- Topics 1519

- Industrial 57

- Troubleshooting Guides 32

- Restaurant Management 142

- Bar Management 66

- Catering Tips 41

- Bakery Management 47

- Food Trucks & Concessions 44

- Advertising & Marketing 40

- Eco-Friendly Tips 11

- Facility Layout & Design 49

- Coffee Shop Tips 31

- Installation & Maintenance 58

- Janitorial & Pest Control 33

- Safety & Sanitation 110

- Startup Tips 111

- Menu Design 11

- Kitchen & Cooking Tips 104

- Hospitality Management 24

- Pizza & Sandwich Shop Tips 28

- Smallwares 39

- Food Prep 101

- Tabletop Items 20

- Disposables 26

- Calculators & Tools 8

- Consumables 71

- Warewashing & Laundry 22

- Cooking Equipment 95

- Food Storage & Refrigeration 54

- Beverage Equipment 39

- Office Supplies 5

How to Choose the Best Walk-In Cooler or Freezer

Last updated on Jan 23, 2026When it comes to outfitting your commercial kitchen with the necessary equipment to store perishable items, investing in a walk-in cooler or freezer is a crucial decision. These large, temperature-controlled storage units offer ample space and reliable cooling capabilities to keep your ingredients fresh and your products at optimal quality. We will explore the different types of walk-in coolers and freezers available, their key features, and important considerations to keep in mind when selecting the ideal unit for your business.

Shop All Walk-In Refrigeration

Skip to the walk-in information that interests you:

There are two basic types of walk-ins: prefabricated and built-in. This guide will focus on prefabricated units, but we first wanted to provide some information about these two styles so you can evaluate which is best for your business. We'll also cover outdoor walk-ins, which can be made in either of the two styles but require some specialized considerations.

1. Prefabricated Walk-Ins

Prefabricated walk-in coolers are a popular choice for businesses looking for a convenient and efficient cooling solution. They're built from pre-made urethane panels that are designed to provide excellent insulation to keep your products at the optimal temperature. Prefabricated walk-in coolers usually come in set layouts and sizes, making it easier for you to choose the right option for your space. This standardized approach can save you time and effort in the selection process.

With their simple design and pre-made panels, prefabricated walk-in coolers can be assembled in a relatively short amount of time, allowing you to start using them sooner. Additionally, prefabricated walk-in coolers are easy to expand. If your business grows and you need more storage space, you can easily add to your existing cooler by purchasing additional panels and components. Whether you are moving to a new location or reconfiguring your space, these coolers can be disassembled and reassembled with minimal hassle.

2. Built-In Walk-Ins

Built-in walk-in coolers are a popular choice for businesses that require a customized cooling solution. These walk-in coolers are typically constructed with insulation covered by structural tiles on the walls and floors, providing excellent temperature retention and energy efficiency. One of the key advantages of built-in walk-in coolers is their ability to be tailored to your exact specifications. This customization allows you to design a cooling space that perfectly fits your business's needs and layout.

However, it's important to note that built-in walk-in coolers are not easily moved or changed once installed. This permanence can be a limitation for businesses that anticipate future layout changes or relocation. Therefore, careful consideration should be given to the long-term needs of your business when opting for a built-in walk-in cooler.

3. Outdoor Walk-Ins

While outdoor walk-ins can either be built-in or prefabricated, they are not interchangeable with indoor walk-ins. Outdoor walk-ins need rainproof roofs to prevent water from leaking into the box. This can be as simple as metal flashing installed over the roof seam or as extensive as a polyvinyl roof system with connectors and a rain hood over the door.

For areas with freezing winters, the unit may require a winterizing kit. This will include a compressor cover, a heater to warm the oil in the compressor for proper circulation, and various other components to help your cooler operate properly in freezing conditions. You may choose to purchase an interior heater kit that will keep refrigerated items from freezing when the ambient outdoor temperature is consistently below 32 degrees Fahrenheit.

At its simplest, a prefabricated walk-in cooler is a large insulated box with a cooling system. Every manufacturer has unique design features and advantages but they all have the same core components: the panels, the floor, the door, and the refrigeration system.

1. Panels

The panels are what help your walk-in stay cold and run efficiently. They consist of insulation foam sandwiched between thin metal sheets, sometimes called the "skin". Here are some fast facts about walk-in panels:

- Price Point: Typically higher costs mean increased durability and corrosion resistance.

- Most Affordable Panels: Aluminum panels tend to offer the lowest price point and all-around good corrosion resistance.

- Highest Quality Panels: Stainless steel panels usually come in at the highest price point and offer the best corrosion resistance.

- Mid-Range Panel Materials: Galvanized steel, aluminum-coated steel, painted steel, and other metals and coatings tend to fall somewhere in between the price and quality points of aluminum and stainless steel panels.

- Embossed Panels: Embossed patterns provide additional strength and reduce the visibility of wear and tear.

- Insulation Considerations: Extruded polystyrene and polyurethane are the most common insulation materials. Both are great insulators, but extruded polystyrene is more resistant to moisture and has a higher structural strength than polyurethane. It also retains more of its insulating capacity (or the R-rating) over its life, whereas polyurethane will lose more of this capacity over time.

2. Floors

You have a choice to order a walk-in with or without a floor included. Ultimately which one you go with depends on how you intend to use the unit and the layout of your space. Use the following information to help guide your decision:

- Included Flooring Benefits: Most included floors are made from smooth aluminum, which is good for general use. These are typically easier to install than a custom floor.

- Floorless Benefits: If you'll be using fully loaded transport carts, heavy shelving units, or otherwise subjecting the floor to heavy loads frequently, you should consider getting a floorless model and installing a ground-contact concrete floor to stand up to these heavier loads.

- Insulated Flooring Benefits: If your walk-in will be located above a basement or in a warm, uninsulated area you will need insulated flooring to keep hot air out and lock cold air in. This reduces strain on your compressor and prevents condensation that can damage the box and create a slipping hazard.

3. Walk-In Cooler Doors

The door is the most used part of your walk-in, and like the other parts of the unit, you may have several options available. Learn more about walk-in cooler doors:

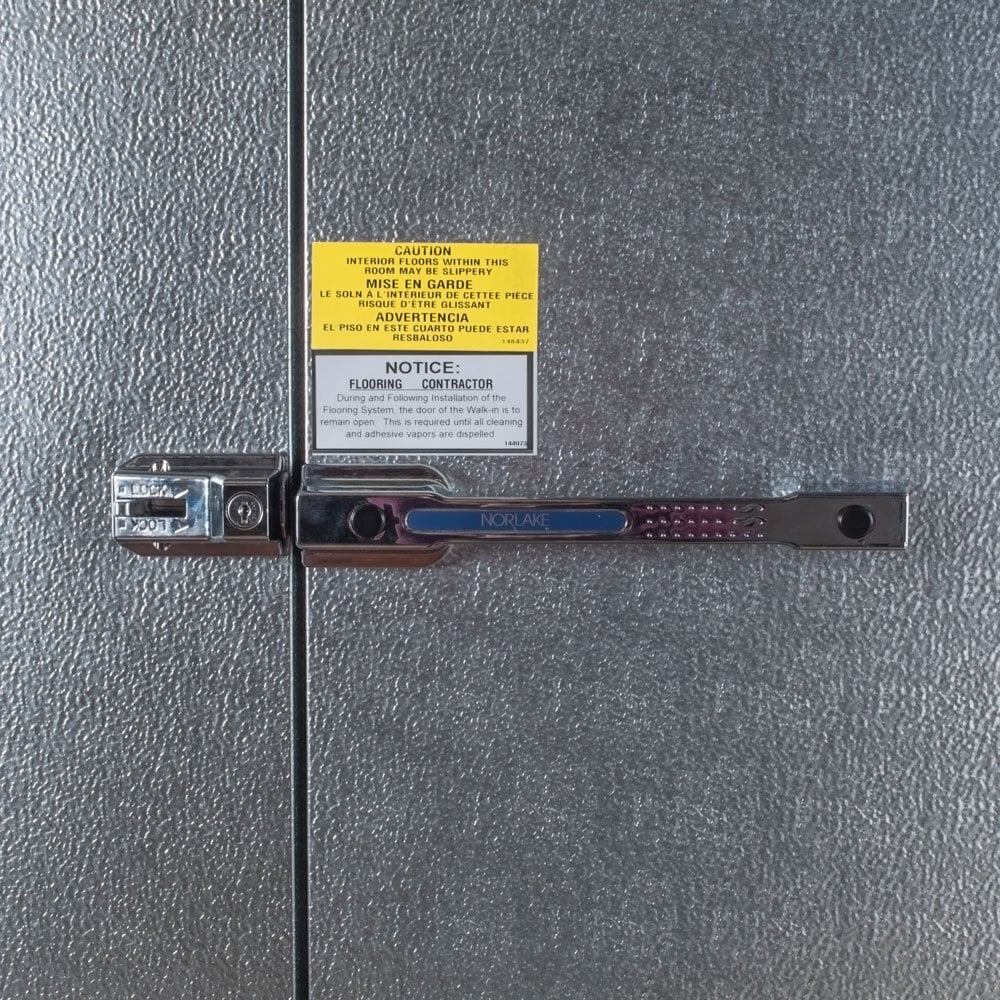

- Maintaining Door Seal: The door receives a lot of abuse as busy employees are understandably more focused on filling orders than the walk-in door. Investing in a unit with high-quality hinges and latches, and durable gaskets will help maintain the door seal for energy efficiency.

- Self-Closing Doors: A self-closing door mechanism is also a good investment as it ensures the walk-in can't be left open accidentally, making it work harder to maintain temperature in the best-case scenario, and causing spoiled product and refrigeration system damage in the worst case.

- Door Features: Some doors may include a small window to see the interior of the unit, or locks to secure food after hours.

Additional Parts and Tools You May Need

Once your cooler is installed, there are still many items you'll need to get it ready for use. To maintain your cooler and ensure that it continues to work properly, we offer everything from cleaning solutions to refrigeration thermometers. And don't forget about shelving and racks! Check out our assortment of walk-in accessories to make sure that you have everything you need once your cooler is up and running.

- Ramps: Will you be rolling carts or pan racks into your new cooler? You may need a ramp to get heavily laden carts over the threshold.

- Pressure Relief Valves: Some municipalities require that a pressure relief valve be purchased with a walk-in. This is a device that prevents the refrigerant from exceeding safe pressure limits. Before making a purchase, you'll want to check your local regulations to see if this applies to you.

- Refrigeration Systems: You have the option to purchase just the walk-in cooler box or just the refrigeration system. If you want to put together a customized combination of box and refrigeration system or replace a broken component, we can help you do just that.

- Shelving: Once your cooler is installed, you'll need shelving to organize and prep it for safe, sanitary food storage. FDA codes require food to be kept away from the walls and at least 6" off the floor. If you are shopping for shelving systems or dunnage racks, our Regency green epoxy or black epoxy wire shelving can help you store food safely so you'll ace your health inspections.

- Refrigerator/Freezer Thermometers: Though exterior temperature displays are a great way to get a quick picture of how the unit is performing, placing refrigerator or freezer thermometers strategically inside your cooler will help you make sure that proper temperatures are maintained throughout the entire box.

- Non-Skid Tape: Smooth aluminum or concrete floors can become slippery in a damp environment. Using strips of non-skid tape can prevent accidents and ensure that your employees stay safe while stocking supplies or retrieving food from the cooler.

- Strip Doors: Adding interior strip doors to any cooler can help maintain energy efficiency and prevent pests from getting inside! When you need to leave your cooler door open for extended periods, to load or unload food, for example, a strip door helps keep cold air in while still allowing workers and carts to easily pass in and out of the cooler.

When it comes to choosing a walk-in cooler, one of the key considerations is the size of the unit. Walk-ins come in a wide range of floor plans and configurations, catering to various storage needs. From tiny boxes that provide a small boost to storage capacity to massive units that can hold vast quantities of food, there is a walk-in cooler size for every commercial kitchen.

You must factor in the potential growth of your business and any seasonal fluctuations in storage requirements. Investing in a slightly larger unit than your current needs dictate can help future-proof your kitchen operations and ensure that you have sufficient storage space as your business expands.

Walk-In Cooler Sizing Calculator

To determine the right walk-in cooler size for your establishment, you must consider the maximum amount of food you need to store at any given time. A helpful rule of thumb to keep in mind is that 1 cubic foot of walk-in cooler space can typically accommodate about 28 pounds of food. By calculating the total weight of the food items you need to store, you can estimate the appropriate size of the walk-in cooler required to meet your storage needs efficiently.

Walk-In Cooler Space Constraints

The most important thing you can do before ordering a new walk-in is to measure your space and read over the relevant literature carefully to ensure that when it's delivered, everything will fit and your installation will go smoothly. There are many walk-in sizes available so you will most likely be able to find the appropriate one for you, even when you have limited space.

- Remember, you are limited by the space you have now or the space you can build.

- Coolers will require extra space on all sides for ventilation.

- Generally, you can expect a minimum of 1" clearance from the interior walls. There should be at least 2" between the top of the walk-in and the ceiling, but each manufacturer will specify this differently.

You must know how much power the refrigeration system needs to cool the walk-in box and where you want to put that system. The available space and layout of your facility will have a big impact on which options are available to you. Typically, walk-in coolers will require a compressor of around 1/2 hp, while walk-in freezers will require a compressor of around 1 hp. However, this is dependent on the size and layout of your setup. Consult product literature for specifics.

You also need to consider how the refrigeration system is controlled and monitored. Regardless of whether you prefer a digital or dial display, you'll want a unit where the controls are easily accessible. If your business uses a HACCP plan, then consider temperature monitoring and recording systems to make data collection easy. Refer to the chart below to easily compare refrigeration system styles.

1. Remote Refrigeration Systems

Remote refrigeration systems operate by placing the condensing unit outside of the building or in a separate mechanical room. This setup helps reduce noise and heat inside the establishment, creating a more comfortable environment for customers and staff. Additionally, moving the condenser outside minimizes the amount of heat generated within the building, which can help lower cooling costs.

- Less expensive to purchase

- Sits outside the building to reduce the walk-in's ventilation needs

- Charged with refrigerant on-site

- Must be assembled and installed by a qualified technician

2. Pre-Assembled Remote Refrigeration Systems

Preassembled remote refrigeration systems offer a convenient solution for businesses looking for a streamlined installation process. These systems come with most parts already assembled, saving time and effort during setup. By opting for a preassembled remote refrigeration system, you can reduce installation costs and ensure a quicker turnaround time for getting your refrigeration system up and running.

- Sit outside the building to reduce the walk-in's ventilation needs

- Pre-charged with refrigerant

- Most parts are already assembled

- Must be installed by a qualified technician

3. Top Mount Refrigeration Systems

Top mount refrigeration systems are a popular choice for commercial kitchens due to their efficient design and convenient layout. These systems feature the refrigeration unit mounted on the top of the cabinet, providing easy access to the storage area below. Here are some key facts about top mount refrigeration systems:

- Self-contained and completely pre-assembled

- On standard units, the evaporator coil may hang down inside the cooler box. With some variations, the evaporator coil is located on top of the box for more usable interior space

- Discharges heat into the building when used on indoor units, which puts added strain on the HVAC system

- Must be installed by a qualified technician

4. Side Mount Refrigeration Systems

Similar to top mount systems, side mount systems are designed to efficiently cool the interior of the walk-in cooler. One key difference with side mount refrigeration systems is that they can be mounted with bolts or brackets to a side panel of the cooler. This feature offers installation flexibility and can be beneficial in certain space configurations.

- Similar to top mount systems, but may be mounted with bolts or brackets to a side panel

- Reduces interior shelf space due to the evaporator coil

- Great for buildings with low ceilings

- Must be installed by a qualified technician

What Temperature Are Walk-in Coolers Kept At?

Maintaining the correct cold food storage temperature in a walk-in cooler is crucial to ensure food safety and quality. According to food safety guidelines, walk-in refrigerators should keep foods stored at temperatures below 41 degrees Fahrenheit.

By keeping foods below this temperature threshold, you can prevent the growth of harmful bacteria and ensure that your ingredients remain fresh for longer periods. It's important to regularly monitor the temperature of your walk-in refrigerator using a thermometer to guarantee that it is operating within the recommended range.

What Temperature Are Walk-in Freezers Kept At?

Walk-in freezers are typically set to keep food frozen around 0 degrees Fahrenheit. This temperature range ensures that perishable items remain frozen solid, preventing the growth of harmful bacteria and preserving the quality of the food. The construction of walk-in freezer panels is typically thicker than refrigerator panels to provide better insulation and prevent heat transfer from the surrounding environment. This insulation helps the freezer maintain the desired temperature more efficiently, reducing energy consumption and ensuring consistent performance.

Refrigeration systems for walk-in freezers are designed to be larger and more powerful than those used for refrigerators. This is necessary to maintain the lower temperatures required for freezing food properly. The increased capacity and power of the refrigeration system help ensure that the freezer can maintain the desired temperature even when it is frequently accessed or when large quantities of warm food are added.

Walk-In Cooler Energy Efficiency Tips

Making your cooler more energy-efficient can increase the cost of the installation, but when it's done right it will help you save money on your energy bill in the long run, and reduce strain on your refrigeration system, which will help it last longer too.

- Most coolers, especially freezers, should be installed on insulated floors with thermal barriers under each wall panel. This reduces temperature transfer to help the cooler run more efficiently.

- Take care that the panels are installed correctly and that the cooler is as leak-proof as possible.

- Design your shelving system in such a way that it allows air to flow freely around the box. Large obstructions can hamper airflow and, in turn, affect cooler efficiency.

- Consider using LED lighting. This is becoming more and more popular as a standard feature but if you have the choice, they use much less energy and last longer than incandescent bulbs.

Keeping your walk-in clean and sanitized not only upholds food safety standards, it helps preserve the integrity of your equipment. Follow these tips to keep your walk-in cooler or freezer in good condition.

- Use an approved cleaning solution like 4 oz. of bleach in a gallon of water or Arctic Kleen freezer cleaner.

- Follow the manufacturer's directions when cleaning to achieve the best results.

- Keep the door in good condition to maintain the unit's energy efficiency and extend the life of the door and the gaskets.

- If any of the gaskets start to wear out, replacing them is a relatively inexpensive way to keep your cooler in top condition.

- Keep the condenser coil clean. Clogged condenser coils put additional strain on the compressor and can cause the refrigeration system to give out.

- Mildew and bacteria can grow on the walls, ceiling, and floor inside a walk-in cooler or freezer, so regularly wipe down all surfaces to prevent the growth of harmful microorganisms.

- Avoid using corrosive chemicals and high-pressure hoses as these can damage the metal skins on the panels.

A walk-in is a big investment and it can be a big hassle to replace one, so make sure that you review the terms of your walk-in's warranty before ordering and consider:

- How long is the unit protected? How long are individual components like the panels and refrigeration system protected?

- Are there specific requirements that must be met to be eligible for warranty repairs? The only thing worse than having to replace a walk-in is finding out that the warranty won't cover the repairs because it was installed incorrectly.

When Should I Buy a New Walk-in Cooler?

A walk-in fridge can last for many years if it is properly maintained, but it loses some of its effectiveness over time. Since new technology is continually being released, it is recommended to replace a walk-in approximately every 15 years. Do you think you may need to replace a walk-in freezer or cooler earlier? It could be time for an upgrade when:

- Starting up a new business or branch location.

- Your old cooler is notably less efficient than it used to be.

- You start to notice wear on the exterior like metal skins deteriorating or separating from the foam insulation.

- The interior starts to collect condensation or frost build-up. This is an indication that the seal is no longer sufficient to prevent air from leaking in and out.

Related Resources

February 2026 WebstaurantStore Coupon Code

Love is in the air, and so are great deals all February long here at Webstaurantstore! Whether you're looking to get ahead of planning for St. Patrick's Day or shopping for supplies and ingredients for the upcoming Lunar New Year, we've got deals for you! Check out our selection of sale items below and don't forget to enter the code LOVE26 at checkout to enjoy up to 20% off your purchases! Looking to save even more? Check out the new Webstaurant Rewards® Visa Business Card ! Sign up for a new card today and start earning rewards on every WebstaurantStore purchase, and save on a WebstaurantPlus subscription. Fall in love with incredible deals on winter disposable items with February's monthly coupon code! Whether you're looking for microwava

Commercial Refrigerator and Freezer Buying Guide

Refrigerators and freezers are staples in any commercial kitchen. Whether you manage a small mom-and-pop shop, a five-star restaurant, or a large-scale catering company , these appliances provide a temperature-controlled environment for storing ingredients and prepared dishes. They help you uphold food safety standards while providing ample storage space to keep your kitchen organized, both of which are crucial in a fast-paced industry. We'll outline the different types of commercial refrigerators and freezers, highlighting what sets them apart to help you find the right fit for your business. Shop All Commercial Refrigeration Equipment Use the following links to explore the different types of commercial refrigerators and freezers: Types of

Chef Base Buying Guide

Whether you're outfitting a new restaurant with essential equipment or upgrading an existing kitchen, choosing the right chef base requires careful consideration of factors such as size, storage capacity, and ergonomic design. For restaurant operators, investing in the right equipment is not just a matter of convenience, it's a critical decision that impacts workflow, staff productivity, and overall operational success. By understanding the features and benefits that align with your kitchen's needs, you can make an informed decision when purchasing your chef base, enhancing efficiency and supporting your culinary team's success. Shop All Commercial Chef Bases Use the following links to learn more about the different purchasing conditions re