A HACCP plan, which stands for Hazard Analysis and Critical Control Points plan, is a systematic approach to food safety. These plans help you identify, reduce, and react to biological, chemical, and physical hazards that may compromise the safety of food products. HACCP plans apply to all stages of the food chain, from production and processing to distribution and consumption. It is important to note that the Food and Drug Administration (FDA) and the United States Department of Agriculture (USDA) require mandatory HACCP programs for certain industry sectors, such as juice and meat processing facilities.

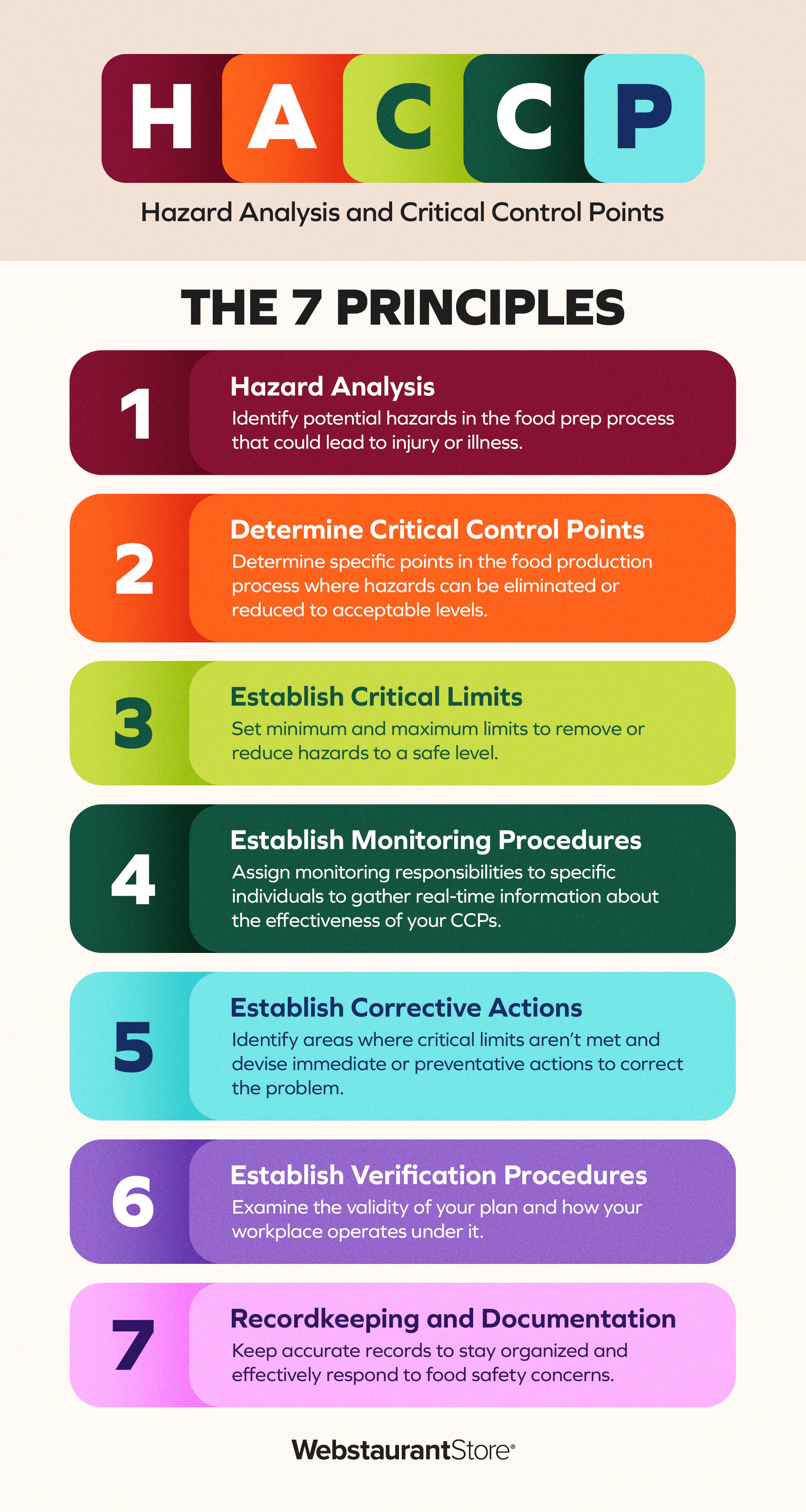

HACCP Principles

HACCP consists of seven formal principles that serve as a framework to prevent injury or illness in a foodservice setting. Understanding these principles and how they apply to your business is essential for creating an effective HACCP plan. By segmenting your HACCP plan, you can easily identify hazards and their causes.

1. Hazard Analysis

Hazard analysis requires managers to identify potential hazards in the food prep process that could lead to injury or illness. When you conduct a hazard analysis, consider all aspects of the food prep process and the flow of food. Time/Temperature Controlled for Safety (TCS) foods are often identified during this step, as they are prone to bacterial growth and can pose a high risk of foodborne illness. Factors that can lead to hazards include how your food arrives, how it is stored, how it is handled, the equipment in your kitchen, the skill level of your employees, and whether you serve populations at higher risk for contracting foodborne illness. Common examples of foods or processes that should be part of a hazard analysis include the following:

- Serving foods without cooking, such as salads, fruit, and cold cuts

- Cooking foods for immediate consumption, like grilled meat

- Chilis, soups, and sauces that are prepped, cooked, held, cooled, reheated, and served

- Foods such as potato salad and coleslaw that are prepped and stored

Example: Raw chicken breast is often prepped, grilled, and served on the same day. The potential danger with chicken is that bacteria may be present in the finished product if it is not cooked correctly. Bacteria are a potential biological hazard.

2. Determine Critical Control Points

Critical control points (CCPs) are specific points in the food production process where hazards can be eliminated or reduced to acceptable levels. In most cases, CCPs are practices or procedures that can lead to cross-contamination when executed incorrectly. To minimize the risk of foodborne illness outbreaks, ask yourself if contamination can occur during a particular process, if you can prevent it through corrective action or steps later in the food preparation process, and how to measure, monitor, and document CCPs. Monitoring helps ensure that CCPs are under control while measuring involves setting specific criteria to indicate whether a CCP is within acceptable limits. Documentation is integral to any HACCP plan, as it helps maintain records of monitoring results, corrective actions, and any other relevant information.

We've listed the common critical control points of a commercial kitchen below:

- Receiving food from your supplier

- Storing food before preparation

- Handling and preparing foods

- Hot or cold holding

- Cooking and reheating food

- Transporting prepared food to a different location

- Holding hot or cold food during service

Example: Cooking raw chicken breast is the only step where bacteria can be eliminated or reduced to a level safe for consumption. Therefore, cooking raw chicken can be identified as a CCP.

3. Establish Critical Limits

Establishing critical limits involves setting minimum and maximum limits to remove or reduce hazards to a safe level. These limits serve as guidelines that are essential for maintaining food safety, and you must track them through measurement or observation. Critical limits should be quantifiable and observable, allowing for effective monitoring and control of the process.

Establishing critical limits provides your staff with strict, easy-to-follow guidelines to keep food safe. They provide a framework for decision-making and help employees understand what actions are required to maintain food safety. Examples of measurable critical limits include the following:

- Temperature

- Time

- PH level

- Water activity

- Available chlorine

Example: To kill bacteria, raw chicken breast needs to be cooked to an internal temperature of 165 degrees Fahrenheit for 15 seconds. This minimum of 165 degrees Fahrenheit for 15 seconds is the critical limit, and this critical limit can be met by cooking the chicken breast on the grill for the appropriate amount of time.

4. Establish Monitoring Procedures

Monitoring procedures provide real-time information about the CCPs in your HACCP plan. They should be easy to perform, meet the specific needs of your establishment, and conform to the requirements of your local regulatory authority. This may involve using appropriate monitoring equipment, such as thermometers, pH meters, or time-temperature recording devices. By regularly monitoring these points, you can identify where, when, and with whom something went wrong, allowing you to take immediate corrective actions.

Assigning monitoring responsibilities to specific individuals is essential to ensure that the monitoring procedures are carried out consistently and correctly. These staff members, typically restaurant managers, should be trained on monitoring techniques to ensure the safety of your guests.

Example: The best way to monitor the chicken is to use a cleaned and sanitized probe thermometer to record the temperature at the thickest part of the chicken breast. Each piece of chicken cooked on the grill must meet the minimum internal temperature of 165 degrees Fahrenheit for 15 seconds.

5. Establish Corrective Actions

Critical limits that aren't met, called deviations, must be dealt with promptly and effectively to maintain food safety standards. Your staff should be prepared with the necessary tools and knowledge to take corrective action and ensure these deviations don't continue to happen. This action can be both immediate and preventative, and any actions you take should meet the standards previously established by your HACCP plan, be based on normal working conditions, and be easily measurable. To ensure accountability and proper implementation, clearly define your staff's roles and expectations and specify who is responsible for implementing corrective action.

Immediate Corrective Action

Immediate corrective action involves addressing the deviation as it occurs to prevent potential harm. Examples of immediate action include the following:

- Throwing out spoiled foods

- Rejecting food deliveries that show signs of pest infestation

- Moving unrefrigerated perishable foods to cold storage

- Throwing out foods that have been in the temperature danger zone for more than four hours

- Sending an employee home if they are experiencing symptoms of foodborne illness

Preventative Corrective Action

Preventative corrective action focuses on identifying and addressing the issue at its root to prevent it from happening in the future. We've listed preventative action examples below:

- Repairing or replacing damaged equipment, dishware, or glassware

- Replacing damaged food preparation surfaces

- Updating workplace procedures to improve food safety

- Appointing a food safety supervisor

- Providing your staff with comprehensive food safety training

Example: If, after checking the chicken breast with the thermometer, the food is not up to temperature even though it was cooked for the appropriate amount of time, then the chicken must continue to cook until it has reached the critical limit of 165 degrees Fahrenheit for 15 seconds. This additional cooking time should be recorded.

6. Establish Verification Procedures

To maintain the effectiveness of your HACCP plan, you should evaluate its performance regularly. This evaluation process, known as verification procedures, involves examining the validity of your plan and how your workplace operates under it. If you implement verification procedures the right way, you'll be able to determine whether or not your plan successfully prevents, reduces, and removes food safety hazards. Examples of verification procedures you can use in your kitchen include the following:

- Reviewing records

- Conducting internal audits

- Testing and sampling food and ingredients

- Performing training and competency assessments

Example: In this step, a manager might review temperature monitoring charts after each shift change to ensure critical limits for chicken breast were met. Looking at the documented temperatures can also help your staff identify trends and adapt their entire process to prevent future hazards.

7. Recordkeeping and Documentation

Keeping accurate records allows you to stay organized and effectively respond to food safety concerns, helping you track progress and making it easy to identify areas of improvement. An accurate recordkeeping process can be time-consuming but is essential to any HACCP plan's success. Train employees so that they know what information to record, how to properly document it, and the significance of their role in ensuring food safety. Common records that are kept about a HACCP plan include the following:

- Time and temperature logs

- Logs of correction action

- Workplace checklists

- Workplace forms

- Employee training records

- Maintenance records

- Standard operating procedures

- Supplier information

- Shipping invoices

- Spec sheets

Example: The temperature monitoring charts, notes about corrective actions, and receiving invoices for the chicken are kept for six months. Specification sheets for the grill and maintenance performed are kept for a year. This information can be used to support and verify the HACCP plan in the event of a problem.

What Is a HACCP Certification?

A HACCP certification is an official recognition that a company has met the necessary food safety standards and a way of assuring customers and regulatory authorities that the business is taking steps to ensure the safety of the food being produced or served. The process of obtaining a HACCP certification can vary depending on the regulations set for your specific area and the type of business you manage. Generally, larger food establishments such as food manufacturers, processors, and distributors are required to have a HACCP certification. Conversely, independent restaurant owners and workers don't usually pursue individual HACCP certifications.

How to Get a HACCP Certification

As with any certification, there are several steps one must go through to obtain a HACCP certification. To get HACCP certified, follow these steps:

- Complete training courses: To begin, complete training courses that cover the principles and requirements of the HACCP system. These courses provide a comprehensive understanding of the HACCP plan and its implementation.

- Contact an NSF auditor: Schedule an NSF auditor to conduct a Good Manufacturing Practice (GMP) audit. This audit will assess your facility's compliance with the HACCP plan and its effectiveness in ensuring food safety.

- Off-site visit: The first part of a GMP audit is an off-site interview, during which you will discuss your HACCP plan and provide necessary documentation.

- On-site visit: Following the off-site interview, the auditor will schedule an on-site visit to your facility. During this visit, the auditor will inspect your facility's operations, including the handling, storage, and preparation of food. They will assess your facility's adherence to the HACCP plan and look for potential hazards that could compromise food safety.

Once the auditor has completed their assessment, they will provide a report detailing their findings. If your facility meets all the requirements of the HACCP plan and demonstrates a commitment to food safety, you will be awarded a HACCP certification.

How Long Does a HACCP Certification Last?

HACCP certifications undergo regular audits to ensure ongoing compliance with the HACCP plan. These audits are typically conducted annually or as required by your certification body.

Important HACCP Terms to Know

When creating, implementing, or reviewing a HACCP plan, it’s important to understand the terminology. Below are a few terms to know:

- Biological Contaminant: Bacteria, viruses, pollens, and other living organisms that may cause illness

- Chemical Contaminant: Substances not naturally found in food that may cause illness (acrylamide, benzene, dioxins, melamine, etc.)

- Corrective Action: Procedures followed when a critical limit is not met

- Hazard: Biological, chemical, or physical contaminant that is likely to cause illness or injury if not controlled

- Monitor: Using a system of observations and measurements to judge whether a CCP is under control and producing an accurate record for future verification

- Physical Contaminant: An extraneous object or foreign matter that may cause injury or illness (bone, string, hair, etc.)

- TCS Food: Food that requires time and temperature control for safety

By adhering to the guidelines outlined in a HACCP plan, businesses can demonstrate their commitment to food safety and maintain compliance with regulatory standards. Additionally, implementing a HACCP plan can help businesses build trust with consumers and protect their brand reputation. Whether you've just started a restaurant or owned one for years, developing a HACCP plan is essential for upholding food safety standards.