Establishing a strong receiving procedure for food deliveries is vital for a successful restaurant operation. In addition to purchasing from approved suppliers, following the correct receiving practices ensures the safety and quality of the food you serve. Mistakes during the receiving process can lead to food waste, financial losses, and customer dissatisfaction. This comprehensive guide will go over what should be done once a delivery arrives, from inspecting to rejecting items.

Tools for Receiving Food

Having the right tools on-hand for your food deliveries is essential to ensure the smooth and efficient flow of goods into your establishment. Designate a specific area in your restaurant for receiving shipments. This area should be clean, well-lit, and well-ventilated. It should also be equipped with shelves or racks to store received items temporarily. By taking the time to organize and equip your receiving area, you can streamline the process and minimize errors. Here are some tools that should be provided to your staff when receiving and inspecting food:

- Scales: Make sure to have a reliable scale in your receiving area. Accurate weighing of incoming items is crucial for inventory control and cost management.

- Thermometers: Maintaining proper food temperatures is vital for food safety. Provide your staff with food thermometers to check the temperature of perishable items upon arrival.

- Box cutters and scissors: These tools are essential for opening packages and inspecting goods. Make sure your receiving area is equipped with a sufficient number of box cutters and scissors. Train your staff on how to properly use box cutters to prevent hand injuries.

- Gloves and hairnets: To maintain sanitary conditions during the receiving process, provide your staff with disposable gloves and hairnets if necessary. This will help prevent cross-contamination and ensure food safety.

Receiving Inspection Checklist

There are various things to look out for when receiving a food delivery, including the vehicle, food quality, and temperatures. Deliveries should be received when your staff has enough time to inspect them and should be accepted by employees trained in food handling and receiving procedures. Use this checklist as a guide during the receiving process on what to check for when a delivery arrives and when to approve and reject items.

Inspect the Vehicle

The receiving process starts with a visual inspection of the food delivery truck. This step ensures that the products you receive are not compromised during the transportation process, ultimately safeguarding the quality and safety of the food you serve to your customers. If there are any problems during your inspection, reject the delivery. Here are a few key points to keep in mind during this process:

- Check for signs of temperature abuse: Make sure refrigerated or frozen items are stored in their designated compartments and their temperature is within the safe range. Look out for signs of thawing, such as condensation or ice crystals, as these could indicate temperature abuse during transportation.

- Look for signs of contamination: Inspecting the vehicle also involves examining the overall cleanliness and condition of the delivery truck. Ensure the interior is well-maintained and free from visible signs of dirt, pests, or other contaminants. Pay attention to the storage areas where the food products are kept, as these should be clean, organized, and free from any potential sources of contamination.

Inspect Food Quality

By implementing a thorough food quality check during the receiving process, you can maintain high food safety standards and ensure that only the freshest ingredients make their way into your dishes. Here are some important things to look for when checking the quality of your incoming food:

- Ice crystals on frozen food: Ice crystals are usually a sign of time-temperature abuse and can indicate that the product has thawed and refrozen. It is best to reject any frozen items that exhibit this characteristic. You should also reject frozen items with fluid or water stains on the packaging or case bottoms.

- Strange or abnormal color or smell: Pay attention to the color and smell of your food products. Any strange or abnormal coloration, such as discoloration or browning, can be a sign of spoilage. Similarly, any unusual or unpleasant odors can indicate that the product is no longer fresh. In such cases, the affected items should be rejected.

- Strange or abnormal texture: Visually inspect the texture of meat, poultry, and fish. Reject items that are slimy, sticky, or dry as well as items that have soft flesh that leaves an imprint when you touch it.

- Moisture on Dry Goods: Even dry goods can be susceptible to moisture, which can lead to mold growth and spoilage. When receiving dry goods, such as flour, rice, or cereal, check for any signs of moisture, including clumping, unusual textures, or water stains on the packaging. Reject any items that show such signs, as they may contain mold or other contaminants.

- Mold: Mold growth is a common issue that can affect various food products. When receiving perishable items, such as fruits, vegetables, or bread, carefully inspect them for any visible signs of mold. Mold can range in color, from green and blue to white or black. If you discover mold on any products, it is imperative to reject them to avoid potential health hazards.

Inspect the Temperature

One crucial step in the restaurant receiving process is checking the temperature of perishable and potentially hazardous foods upon delivery. This is especially important for foods more susceptible to bacterial growth and spoilage due to temperature fluctuations. Measure the temperature of perishable items using a food thermometer to ensure that they are delivered within safe temperature ranges. If a shipment of food is received in the danger zone, it should be rejected and returned to the supplier.

Perishable items that must be inspected include:

- Cold TCS foods: Meat, poultry, dairy, and egg products are all TCS foods that must arrive at or below 41 degrees Fahrenheit (5 Celcius) to ensure their freshness and safety.

- Live shellfish: Live shellfish, such as clams, mussels, and oysters, should be received at a temperature of 45 degrees Fahrenheit (7 Celcius) or lower. The shellfish should be cooled to 41 degrees Fahrenheit (5 Celcius) or lower within four hours of receiving it.

- Shucked shellfish: If you're receiving shucked shellfish, like oysters or scallops, it's important to ensure they are delivered at a temperature of 45 degrees Fahrenheit (7 Celcius) or lower. The shellfish should be cooled to 41 degrees Fahrenheit (5 Celcius) or lower within four hours of receiving it.

- Shell eggs: Shell eggs, which are just fresh eggs in the shell, should be received at an air temperature of 45 degrees Fahrenheit (7 Celcius) or lower. This temperature range is a crucial part of egg food safety to prevent the growth of Salmonella, a common bacteria found in eggs.

- Milk: Dairy-based milk should be received at a temperature of 45 degrees Fahrenheit (7 Celcius) or lower.

- Hot TCS food: Any hot TCS food, such as cooked meats, soups, or sauces, should be received at a temperature of 135 degrees Fahrenheit (57 Celcius) or higher.

- Frozen food: Frozen food items, including vegetables, meats, or pre-made meals, should be frozen solid when received. They should be received and stored at a temperature of 0 degrees Fahrenheit (-18 Celcius) or lower. This temperature range helps to maintain the integrity of the frozen products, ensuring they remain safe and free from freezer burn.

Inspect Packaging

Another crucial step in your receiving procedures is to check the items' packaging. Properly inspecting the packaging ensures that the products you receive are in good condition and safe for use. Here are a few key factors to consider when checking the packaging:

- Check for signs of damage: Carefully examine the packaging for any signs of damage, including tears, punctures, or holes. Packaging, whether it contains food or non-food items, should be intact and clean. If it is not, reject the item and address the issue immediately with the delivery driver or supplier. Reject cans with missing labels, bulging ends, rust, or severe dents. Items packaged in a reduced-oxygen environment that are bloated or leaking, items with broken cartons or seals, and items that appear to be tampered with or repackaged should also be rejected.

- Check for liquids: Reject any items that are leaking, damp, or have water stains as this indicates the packaging was wet at some point.

- Check for signs of pests: Pests, such as rodents or insects, can cause significant damage to your food supply and contaminate your products. Check for any signs of pest infestation, including chew marks, droppings, or live insects. If you notice any indications of pests, it is important to reject the entire shipment to prevent contamination in your restaurant.

- Check expiration dates: The date should be clearly labeled on an item’s packaging. Expired items or items past their use-by date should never be accepted, as they may pose health risks to your customers. It is important to rotate your stock accordingly to prevent the use of expired products and reduce food waste.

Check Documents

One important aspect that cannot be overlooked in your receiving procedure is the checking of documents. These documents serve as crucial records of the items being delivered and help ensure the quality and safety of the ingredients used in your establishment. Below we’ve highlighted some key documents to check for every delivery as well as specific documents to check for certain types of products.

- Invoice: The invoice is the most basic document that accompanies any food delivery. It provides a detailed breakdown of the items ordered, their quantities, and their prices. By cross-checking the invoice with the actual items received, you can ensure that you are being billed correctly and that you have received all the items you ordered.

- Shellfish with Shellstock Tags: When receiving shellfish, it is important to check for shellstock tags. These tags provide information about the source of the shellfish, including when and where they were harvested. By verifying the tags, you can ensure that the shellfish meets the necessary safety standards and has been properly handled.

- Raw or Partially Cooked Fish: Fish that will be consumed raw or partially cooked must indicate that it was frozen correctly before being received. This information is vital because proper freezing kills parasites that may be present in the fish. This will help ensure that you are receiving fish that meets food safety standards and is safe for consumption.

- Farm-Raised Fish: Farm-raised fish have become increasingly popular in the restaurant industry. When receiving farm-raised fish, check the documentation to ensure it was raised to FDA standards.

How to Check Food Temperatures for Receiving

Now that you know the temperatures to receive perishable foods, you may wonder what the proper method of taking these temperatures is. Utilize a thermometer during receiving to ensure food items are at the appropriate temperature. In case you're unsure of how to use one, we will guide you on the precise locations to insert it for the most accurate reading.

- Meat, poultry, and fish: Insert the thermometer stem or probe into the thickest part of the food (usually the center).

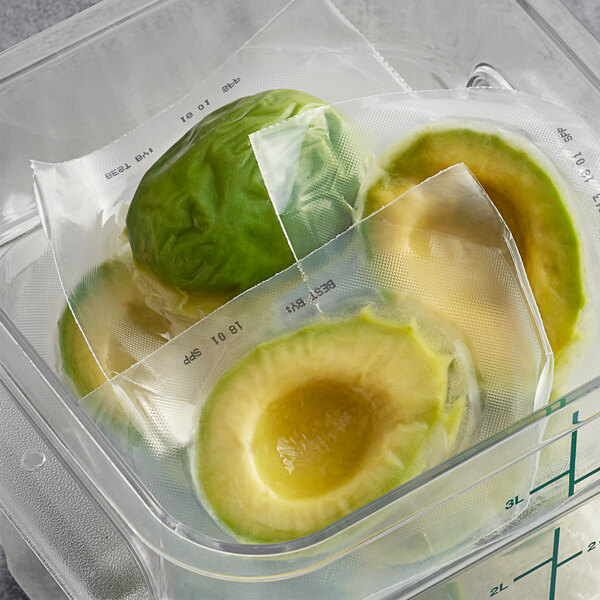

- Reduced-oxygen packaging (ROP), MAP, vacuum-packed, sous vide, and frozen food: Insert the thermometer probe or stem between two packages, being careful not to puncture either package. If the package allows, you can fold it around the stem or probe.

- Other packaged food: Open the package and insert the thermometer stem or probe into the food. Fully submerse the sensor area into the food and be careful not to touch the packaging to ensure an accurate reading.

Restaurant Receiving FAQ

If you're still looking for answers, check out some common restaurant receiving questions below:

Which Items Should Be Stored First?

When receiving a food delivery, cold foods should be put away and stored first. This is to prevent the foods from lingering at hazardous temperatures and reduce the risk of foodborne pathogens.

What If I Need to Reject an Item?

If a food item fails to meet your standards during the inspection, separate it from the accepted items and tell the delivery driver what is wrong with it. Log the rejected item on your receiving report and adjust your invoice accordingly.

When Are Key Drop Deliveries Allowed?

Key drop deliveries are a convenient way for restaurants to receive deliveries when they are closed or unable to be present at the time of delivery. Key drop deliveries must be inspected once a manager or food hander arrives at the operation and must meet the following criteria to be accepted:

- Items are stored correctly as refrigerated, frozen, or dry goods and maintain the required temperatures.

- Items are not contaminated and are protected from contamination.

- Items are honestly presented.

Effective receiving procedures are essential for any restaurant looking to streamline operations, maintain quality control, and optimize inventory management. By implementing a systematic approach to receiving deliveries, you can ensure accuracy, efficiency, and cost savings while also fostering strong supplier relationships and demonstrating compliance.