Properly shipping goods to your customers comes with a lot of variables to keep in mind, like which corrugated box is best for orders, or how to ship your small business's goods at the best price. And when you're working in a distributing center, knowing how to stack a pallet to make sure the contents aren’t damaged is the top shipping priority.

Pallet stacking is more than getting the boxes perfectly packed. It’s what keeps your employees safe from boxes toppling over, as well as optimizing freight costs so you make money from your endeavors. Below we have outlined how to stack a pallet, the best pallet stacking patterns, and how to stack mixed boxes on a pallet.

How to Stack Boxes on a Pallet

Listed below is the best way to stack a pallet:

1. Inspect Your Pallet

As a crucial type of material handling equipment, your pallet is the true base of your structure. If there are any cracks or broken pieces, then your box structure will lean or fall. Take a second to inspect the pallet to make sure it is structurally sound. A great way to keep your pallets organized, safe, and all in one place is to try using a pallet rack.

2. Plan Your Pallet Stacking Pattern

Take a look at what boxes are in the shipment order and what they contain. If they are all different sizes and weights, or all the same size box yet very heavy, you’re best off using a type of interlocking pattern. If the boxes are the same size and low-density, then a columnar stacking pattern is best.

3. Place Heaviest Boxes Down First

Having the heaviest boxes on the bottom creates the most stable base, prevents lighter packages from getting crushed, and also creates a lower center of gravity for a stronger structure. Practice placing the boxes with the barcodes facing outwards so shippers and receivers can see what contents are in the boxes right away.

4. Line Up Boxes Close to the Edge

When placing your first layer, bring the boxes as close to the edges as possible without them overhanging at all. Each layer should then line up with the first layer so no overhang happens as you build upwards. When boxes hang over the pallet, the box strength can reduce by 30% or more, not to mention possible freight damage while shipping and handling.

5. Fasten with Straps

Now that your boxes are all set on the pallet, you need to fasten them onto the pallet using strapping bands. Use heavy-duty straps that are made from materials like polypropylene, polyester, or steel.

Use two straps on either side to secure the load vertically and horizontally. There should not be more than 3 inches of space between the box and the pallet or else the strap cannot secure down the bottom boxes and they will slide around during transit.

6. Secure with Shrinkwrap

Once the boxes are strapped in, use shrink-wrap on the entire perimeter of the structure. You can do this by hand or invest in a shrink-wrap machine if shrink-wrapping is very common in your facility. A great alternative to shrink-wrap boxes instantly is with pre-made pallet covers.

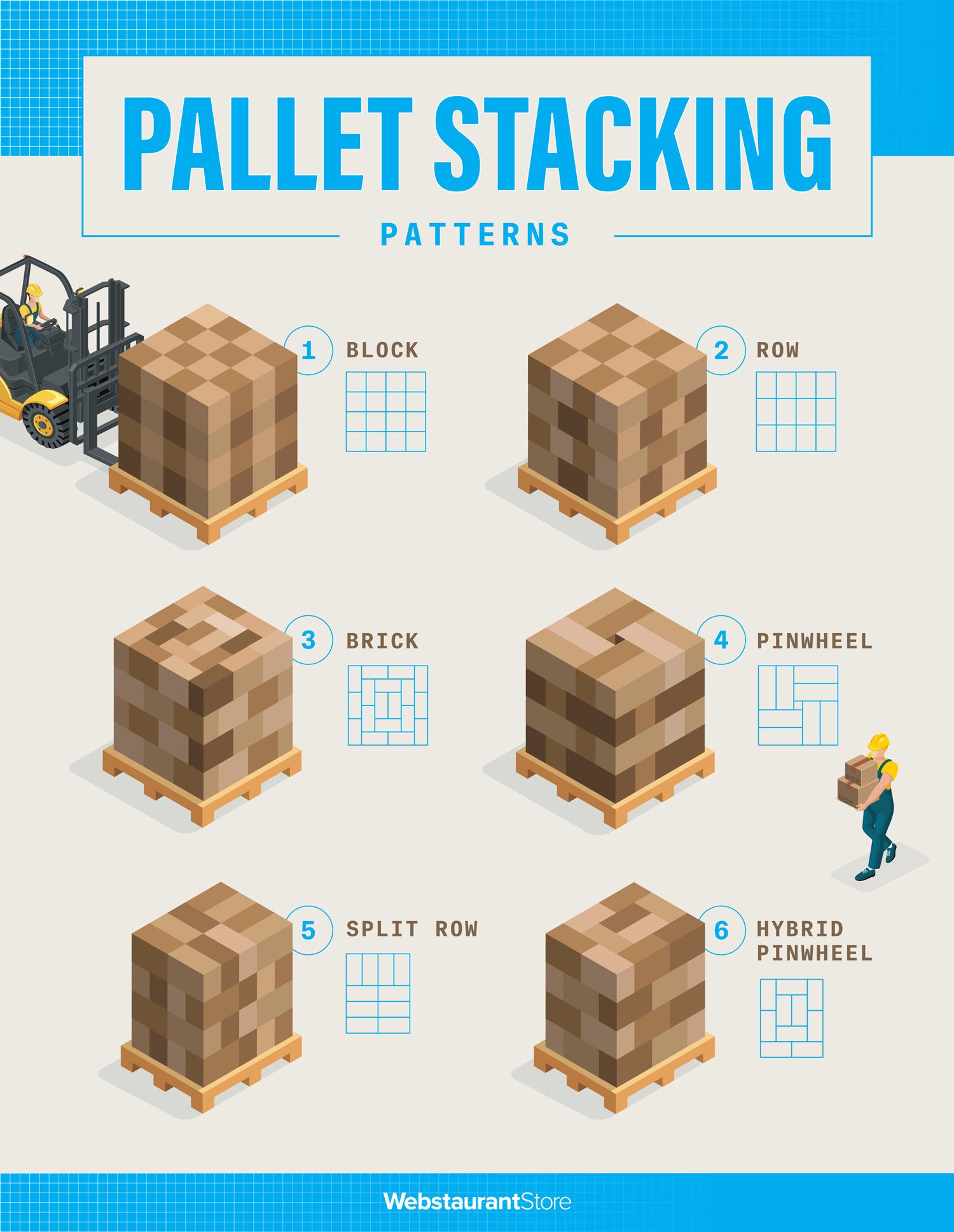

Pallet Stacking Patterns

There are a ton of different pallet stacking configurations you can use to secure your freight, and the final pallet stacking pattern ultimately depends on the box sizes and weight. Below are different pallet stacking patterns your employees can utilize when palletizing boxes.

Column Stacking vs. Interlock Stacking

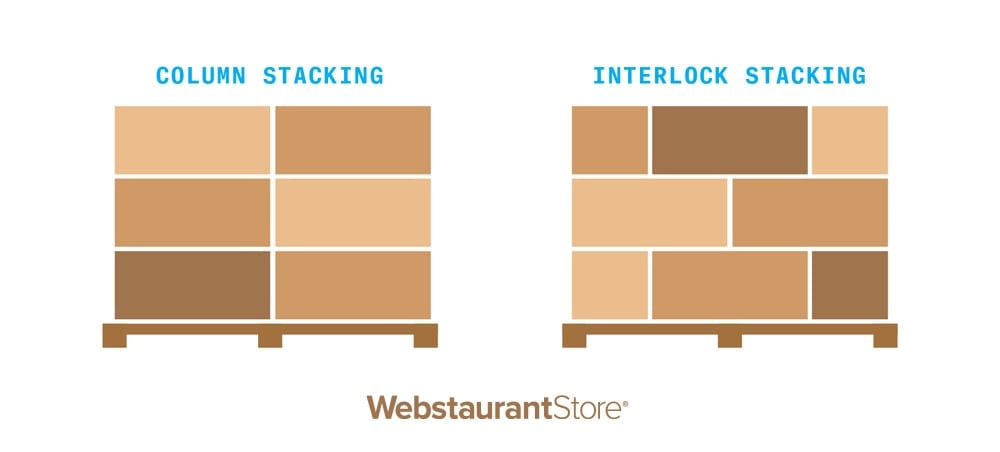

But which pattern is the best way to stack boxes on a pallet? Well, it depends on what you're stacking. The biggest idea to keep in mind is whether you need to column stack or interlock stack. The difference between column stacking and interlock stacking is the way the boxes are placed on each other layer by layer, building specific patterns that lend their strengths and weaknesses to the overall stability of the stack.

To decide whether you should use a column stacking or interlock stacking pattern, we have the benefits and disadvantages of each type listed below.

Column Stacking

In the diagram above, you can see that column stacking is when each box is placed directly over the box underneath it so the edges line up perfectly. This method is best for lighter density loads such as soft or fragile contents.

Column stacking is the most common type of pallet stacking pattern, although there are both benefits and drawbacks to this pallet stacking method.

Column Stacking Benefits

- Improves box security and strength by 30-50%

- Resists compression from shrink-wrap

Column Stacking Disadvantages

- More susceptible to toppling if too tall of stacking height

Interlock Stacking

As shown in the above diagram, interlock stacking uses a type of rotating method when placing boxes so that more than one box below is supporting the box above it. This method is best for higher-density loads, such as canned goods and other heavy contents.

Many believe that this is the superior way to palletize boxes, but there are both advantages and disadvantages to this pallet stacking method, too.

Interlock Stacking Benefits

- Provides the most stability

- Best method for diverse box shapes and weights

Interlock Stacking Disadvantages

- Can have fewer goods per pallet

- May create more pressure on individual boxes from uneven weight distribution

How Do You Stack Mixed Pallet Boxes?

Depending on your operation, you may have to build a pallet differently each time with diverse box shapes and weights. While it may not be the most fun game of Tetris, there are tips to make stacking a pallet with mixed boxes easier:

- Start with the larger, heavier boxes. Having larger boxes on the bottom creates a solid foundation and resists leaning.

- If the smaller boxes are a lot heavier than the larger boxes, place the smaller, heavier boxes as the first layer, then place the larger, lighter boxes on top. This will ensure that the heavier boxes are not crushing the lighter boxes, causing the stack to lean.

- Try to keep the same size boxes side by side.

- Organize each layer so it reaches the ends of the previous layers’ boxes.

- Keep the square or rectangular shape of the pallet and avoid making a pyramid. The shape is what gives structure to the pallet.

- When finished stacking the pallet, run packing tape around each layer to provide a bit more strength.

What Is Pallet Stacking?

Pallet stacking is strategically placing all of the boxes for a shipment on a pallet. Properly stacking pallets is crucial to maintaining the integrity of your shipped goods and, more importantly, keeping your warehouse employees safe from the hazards that a poorly stacked pallet can impose.

Practicing proper pallet stacking is imperative if you operate a warehouse. It could make or break your reputation, ensure you’re earning money from your operation, and above all, keep your employees safe from haphazardly made pallet stacks. Familiarize yourself and your warehouse employees with these pallet stacking patterns and best practices so you can run a successful warehouse operation.