Multiple factors must be considered when starting a warehouse business to make your facility efficient and profitable. In the hustle and bustle of a warehouse, safety must be a top priority to ensure that every employee is protected from hazardous materials that may exist in their workspace. Adding an emergency shower and eyewash station as a form of first aid can make all the difference in preventing injury and permanent bodily damage. Read on to find out if your warehouse may require eye wash stations and safety showers, how they must operate to meet OSHA regulations, and how to use them.

Shop all Eye Wash Stations & Emergency ShowersWho Is Required to Have an Eye Wash Station?

According to OSHA 29 CFR 1910.151(c), eyewash stations and safety showers are a required form of first aid in settings where hazardous or corrosive materials may come in contact with the skin or eyes of any person present. These materials may require drenching or flushing to ensure the safety of the exposed person. Facilities that have open tanks of corrosive materials, toxic substances (like those used for dipping and coating products), or toxic cleaning chemicals must have emergency showers and eye wash stations to protect workers from spills or splashes.

The following are some of the chemicals and materials that are considered toxic or corrosive and can cause permanent damage if encountered with the eyes or skin.

- Formaldehyde

- Methylene Chloride

- Ethyleneimine or beta-Propiolactone

- Petrol and Diesel

- Chloroform

- Molten Metals

- Oxidizing Agents

- Alkylating Agents

- Dehydrating Substances

If your facility uses these chemicals, you may be required to install eye wash stations and safety showers. Foodservice facilities like restaurants and cafeterias may need eye wash stations depending on the cleaning chemicals they use. Laboratories and educational facilities may also require eye wash stations based on the chemicals they use. Check with your local jurisdiction to find out the specific requirements for your establishment and the chemicals you use. Train staff members on safety abbreviations so they know the risks of the materials they're working with. Be sure to put up Understanding Hazardous Material Labels" posters so your staff can easily identify toxic materials.

What Is an Eye Wash Station?

Eye wash stations and emergency eyewash devices are used to flush hazardous materials from the eyes and face to prevent long-term damage. They spray water upward to remove toxic, corrosive, or harmful chemicals that may have come in contact with a person's eyes, face, or neck. An eye wash station is the first step in the first aid care of a person exposed to harmful materials and should always be followed up with professional medical care.

Types of Eye Wash Stations

There are three types of emergency eye wash stations with their own set of requirements. The type you choose for your business will depend on the setting where your employees are working with hazardous materials.

- Plumbed Eyewash Stations - A plumbed eyewash station is piped directly into a waterline, like a water fountain, making it a permanent fixture in your facility. This provides the eyewash station with a constant source of running water when needed. They are useful in facilities that regularly work with corrosive and toxic chemicals.

- Self-contained Eyewash Stations - A self-contained or gravity-fed eyewash station features a tank of flushing fluid that is forced by gravity to the opening of the device. The flushing fluid must be regularly replaced or refilled after use to ensure it is available to complete the task when needed. They are mostly used in locations that occasionally work with corrosive and toxic chemicals.

- Eye Wash Bottle Stations - A portable eye wash bottle is a bottle that can be dumped on an open eye in the event of a toxic chemical splash. They are useful in remote work environments where a person may need to rinse their eyes before they can make it to a plumbed or self-contained unit. They should not be used as a substitute as they do not contain enough fluid to flush out the eye completely.

Note: A person should seek emergency medical assistance after using any type of eye wash station.

Eye Wash Station Requirements

The eyewash station requirements were created by the American National Standards Institute (ANSI) and the International Safety Equipment Association (ISEA) with the support of OSHA. For detailed information on OSHA eyewash requirements, refer to the ANSI/ISEA Z358.1 and your local jurisdiction. The following are just some of the general requirements one must follow when installing and using eyewash systems in their facility.

Eye Wash Station Location

The location of an eye wash station must meet the following requirements:

- Must be located within approximately 55 feet of hazardous material worksites

- Must be accessed within 10 seconds after an incident

- The path to the eye wash station must be clear of obstructions

- Must be installed in a well-lit area

- Must be clearly marked with appropriate and highly visible signage

- The eye wash station height should be within 33 to 53 inches from the ground and 6 inches away from the nearest obstruction

Eye Wash Station Temperature

The temperature of the flushing fluid should be tepid, or between 60 to 100 degrees Fahrenheit and remain so for 15 minutes of continuous flow. Any temperature above 100 degrees Fahrenheit can cause burns and serious damage to the eye. Temperatures below 60 degrees Fahrenheit may offer momentary relief, but expended use can drop the body temperature and cause hypothermia.

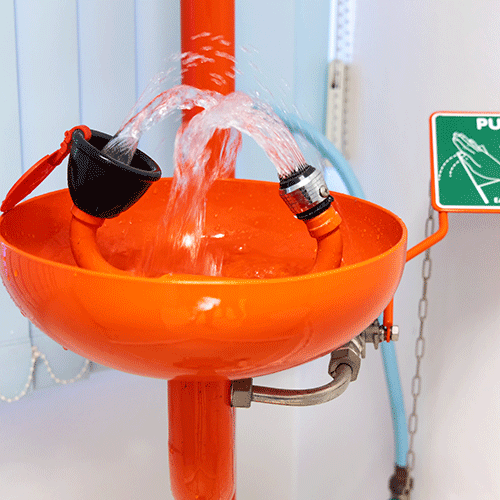

Eye Wash Station Flow Rate

The flow rate of an eye wash station must be high enough to flush out the contents from an eye but low enough not to damage the sensitive tissue. Eye wash stations must deliver at least 0.4 gallons of water per minute (GPM) from each spray head for 15 minutes. Eye and face combination units must supply at least 3 GPM. Most units will range between 1 to 4 GPM. There should also be sufficient flow for the water to open the spray head covers automatically and for the user to stand about 8 inches from the spray head.

Eye Wash Station Maintenance

An eye wash station requires weekly activation to flush the fluid regularly and ensure that the unit is working properly. Weekly activation prevents stagnant water from sitting for too long and creating mineral build-up. This also allows you to catch any blockages or leaks early and fix the unit so it is ready for use at a moment's notice. For self-contained units and eye wash bottles, you’ll want to check the fluid levels at this time and ensure that there is sufficient fluid for a continuous flushing session. You’ll need to perform a thorough inspection of the unit once a year to remain in compliance with ANSI/ISEA Z358.1.

How to Use an Eye Wash Station

Regardless of their warehouse position and tasks, your staff members must be familiar with how to use an emergency eyewash station in the event of a spill or splash. Train your employees to follow the steps below:

- Act immediately. Even a minor splash can cause permanent damage. Do not hesitate to use the eye wash station if potentially toxic materials come in contact with the skin or eyes.

- Push the lever. There should be a clearly marked lever that activates the flushing fluid and pops off the dust covers on the spray head.

- Lower eyes to the water stream. Holding your eyelids open with your fingers, allow the water to flow over your eyes while rolling then gently up and down, from side to side.

- Use the unit for 15 minutes. Keep flushing your eyes for a full 15 minutes. Removing your eyes before the 15-minute mark may cause permanent damage. (*If you are wearing contacts, begin flushing your eyes first, then pause to remove your contacts and continue flushing.)

- Seek medical assistance. Once the 15 minutes are up, have a colleague or emergency department escort you to the closest hospital to have your eye tended to by a medical professional. Do not drive yourself as your vision may be impaired.

Training your staff to understand safety datasheets can help them learn the first-aid measures necessary when working with certain materials and allow them to quickly react if an eye wash station is needed.

What Is a Safety Shower?

A safety shower, also known as an emergency shower, dench shower, or decontamination shower, is used to thoroughly rinse off hazardous materials that may have come in contact with a person's head or body. Drenching the body after contact with corrosive or toxic chemicals can help prevent burns, scarring, permanent damage, or even death in hazardous settings. Safety showers may be a requirement in factories, laboratories, medical facilities, schools, and chemical plants. A person using a safety shower should always seek medical attention after coming in contact with hazardous materials.

Types of Safety Showers

An emergency shower may be needed in your facility to ensure and enforce warehouse safety. Depending on the work done in your establishment, you may be required to install a specific type of safety shower to protect your staff. The following are some of the most common safety shower types you may encounter:

- Plumbed Safety Shower Stations - Plumbed safety showers are permanent fixtures that are connected directly to a waterline. A plumbed emergency shower can be either ceiling-mounted, wall-mounted, or floor-mounted. This system provides flowing water at the pull of a lever to drench the person and wash away toxic chemicals.

- Self-contained Safety Shower Stations - Self-contained safety showers feature a tank of flushing fluid that is sprayed through the showerhead when the lever is pulled. This tank must contain enough fluid to dispense 20 gallons of water per minute for 15 minutes. The unit will need to be refilled between uses to ensure there is enough fluid for emergencies.

- Combination Safety Shower Stations - A eye wash and safety shower combination station features both a showerhead and an eye wash faucet. These units are typically plumbed into the building and ensure that you are prepared for any situation involving hazardous materials.

Note: After a person uses an emergency shower, they should seek immediate medical attention.

Safety Shower Requirements

Emergency shower requirements are listed by the ANSI and put in place to ensure that your staff members can seek immediate relief from spills and splashes while working with hazardous materials. Depending on the facility, a business can receive heavy fines for not complying with ANSI and OSHA safety shower regulations.

Safety Shower Location

The following are the requirements you should follow for the location of your emergency shower:

- Accessible within 10 seconds of the incident

- Located within approximately 55 feet of and on the same level as hazardous materials

- Has a clear path to the shower, free of obstructions

- Area must be well-lit and clearly marked with signage

- The handle or activation lever is no more than 69 inches above the ground

- If enclosed, the diameter of the shower should be a minimum of 34 inches

Safety Shower Temperature

To ensure that your safety shower doesn't cause further harm to an individual, your emergency shower temperature should be set between 60 to 100 degrees Fahrenheit. The shower should be able to maintain this temperature for approximately 15 minutes to rinse away as much toxic material as possible. If the temperature is above 100 degrees Fahrenheit, the person may receive burns from the water. Lower than 60 degrees Fahrenheit, the water temperature of a safety shower may cause hypothermia.

Safety Shower Flow Rate

An emergency shower requires a minimum flow rate of 20 GPM with a pressure of 30 lbs. Per square inch for at least 15 minutes. The height of the showerhead should be approximately 80 to 96 inches above the surface where the user will stand.

Safety Shower Maintenance

To keep your emergency shower operating smoothly, you’ll need to perform regular maintenance. Activate your safety shower once a week to flush out any sedentary fluid. You’ll also need to conduct a thorough inspection annually to meet OSHA and ANSI requirements.

How to Use a Safety Shower

To enforce safety standards in your establishment, be sure to thoroughly train and regularly review the step-by-step instructions for using a safety shower with your employees. The following are the directions for how to use an emergency shower:

- Don’t delay. Take immediate action if toxic or corrosive chemicals make contact with your skin, either directly or soaked through clothing. Any delay can cause serious and permanent damage.

- Remove all clothing and jewelry. This may be uncomfortable in a work setting, but saturated fabric can cause severe injuries on the skin and may not be fully free of chemicals when rinsed. Jewelry can also retain toxic chemicals in nooks and crannies which is why they should all be removed and thoroughly cleaned before wearing again.

- Turn on the water. Most safety showers feature an activation lever that needs to be pulled to turn on the water stream. Stand in steam for 15 minutes. You’ll need to stand in the water for a minimum of 15 minutes to prevent as much damage to your skin as possible.

- *Use an eye wash station, if needed. If your eyes are also contaminated, use either an eye wash bottle or the connected eyewash station to rinse them. Do not use the water from the shower to wash your eyes. The flow rate of a safety shower is too high and may cause permanent damage to the eyes from the pressure.

- Seek medical assistance. Either wait in the water stream for medical assistance to arrive or have a coworker drive you to the closest hospital after completing a 15-minute safety shower rinse.

A safety shower is only a precautionary measure to reduce injuries and should not be used as a substitute for professional medical care. Ensure that your employees are familiar with emergency shower safety procedures and know when to use them.

An industrial facility can be a hazardous environment if your staff is not trained in the appropriate health and safety measures. Along with forklift safety and ladder safety, prepare your staff to quickly and efficiently react to spills and splashes involving toxic chemicals to prevent injuries and create as safe of a workspace as possible.