Grease traps are essential components in commercial kitchens and foodservice establishments. These devices play a crucial role in preventing fats, oils, and grease (FOG) from entering the municipal sewer system, where they can cause blockages and environmental damage.

Shop All Grease TrapsWhat Is a Grease Trap?

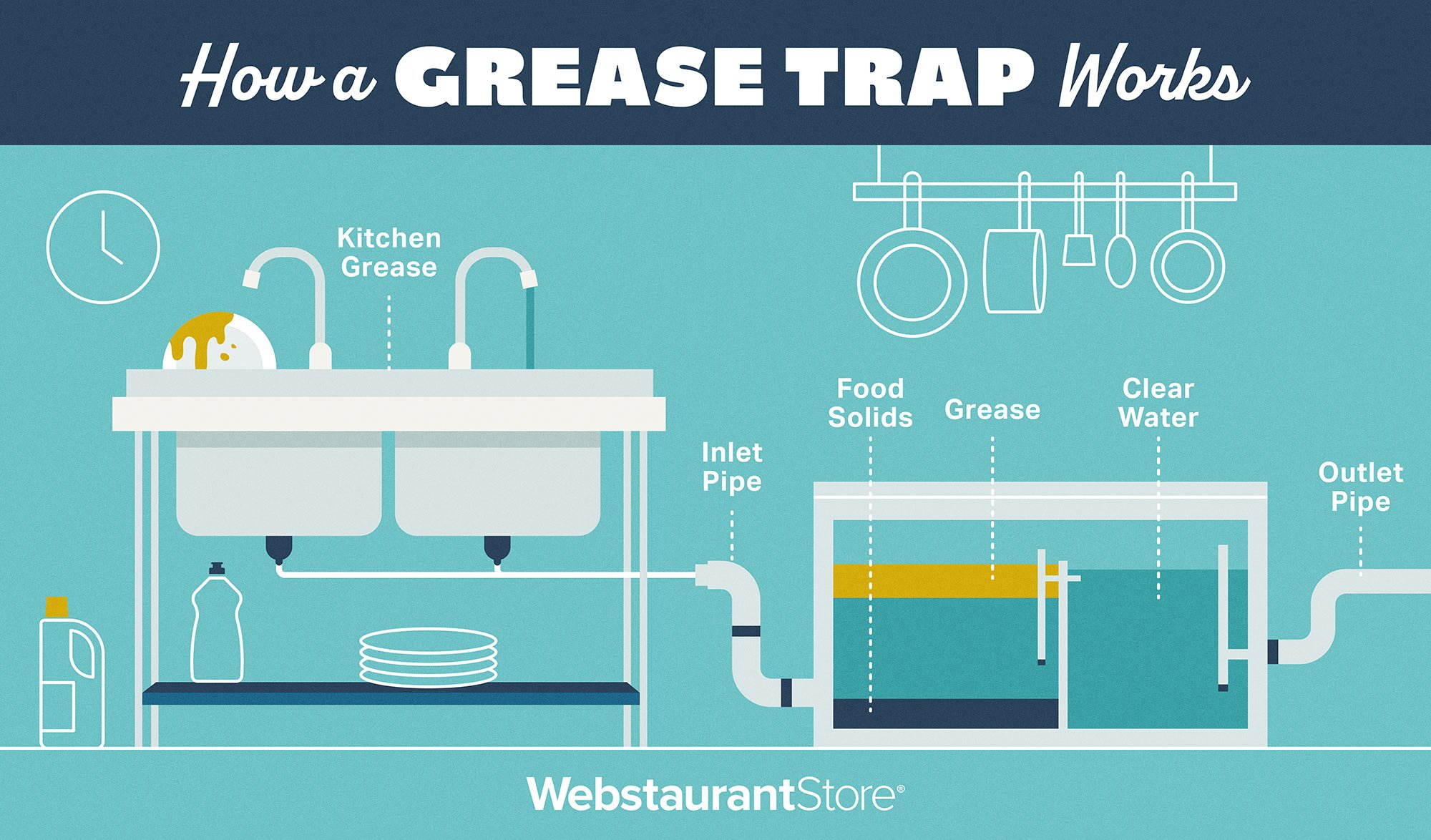

A commercial kitchen grease trap is a plumbing device that intercepts and captures FOG before it can flow into the sewer system. It's typically installed in the wastewater drainage system of a kitchen, usually underneath sinks or below the floor. Grease traps work by slowing down the flow of wastewater, allowing FOG to separate and float to the top while solids settle at the bottom. This separation process helps to prevent FOG from accumulating in pipes, which can lead to costly clogs and backups.

Grease traps area availale in a range of sizes and configurations to accommodate the needs of different commercial kitchens. They're constructed with durable materials such as stainless steel, plastic, or cast iron to withstand the demands of a busy kitchen environment. Proper maintenance and cleaning of grease traps are essential to ensure they function effectively and comply with local regulations.

What Does a Grease Trap Look Like?

Typically, a grease trap consists of a large, durable container that's rectangular in shape and made of materials such as stainless steel, plastic, or concrete. The interior of a restaurant grease trap is divided into compartments that slow down the flow of wastewater, allowing FOG to separate and rise to the surface. The trap is equipped with inlet and outlet pipes to facilitate the flow of wastewater through the device. Some grease traps also have a strainer or baffle system to capture solid food particles and prevent them from clogging the system.

How Does a Grease Trap Work?

The mechanics behind a grease trap are actually very simple. The principle of gravity and buoyancy dictates that high-density materials will sink in water and low-density materials will rise. Wastewater flows down the sink drain and enters an inlet pipe leading to the grease trap. When the water flows into the trap, solid food scraps sink to the bottom of the trap (high-density), the grease and oil rise to the top (low-density), and the water continues flowing forward out of the trap to the outlet pipe. This water has now been clarified, which means the solids and grease have been intercepted and remain in the trap.

Grease Trap Diagram

Check out the diagram below for a visual representation of how water flows through the grease trap:

The Benefits of Grease Traps

Grease traps have several benefits beyond intercepting FOG and keeping it out of the sewage system:

- Prevents Costly Plumbing Issues: One of the main benefits of grease traps is that they help prevent clogs and blockages in the plumbing system. Without a grease trap, grease and solid materials can accumulate in pipes over time, leading to costly repairs and potential downtime for the restaurant.

- Improved Kitchen Hygiene: Grease traps help maintain a cleaner and more hygienic kitchen environment. By trapping grease and solid waste, they reduce odors and the risk of attracting pests, creating a more pleasant and sanitary workspace for kitchen staff.

- Extended Equipment Lifespan: Grease traps can also help extend the lifespan of kitchen equipment, such as dishwashers and garbage disposals, by preventing grease buildup in the plumbing lines connected to these appliances.

- Environmental Protection: Grease traps not only protect your plumbing system but also help protect the environment. By capturing grease and other pollutants, grease traps prevent these substances from entering the sewer system and contaminating water sources.

Grease Trap FAQ

We answer some common questions about grease traps below:

Am I Required to Install Grease Traps in My Restaurant?

Many municipalities and local health departments have specific regulations mandating the installation of grease traps in commercial kitchens. These regulations are in place to prevent grease and other solid materials from entering the municipal sewage system, which can cause blockages and environmental damage. The size of your restaurant and the volume of food preparation activities can also determine whether you are required to install a grease trap. Larger establishments that handle a high volume of greasy foods are more likely to be mandated to have grease traps in place.

Even if not required by law in your area, installing a grease trap is a responsible practice to minimize the environmental impact of your restaurant's operations. Grease traps help prevent fats, oils, and grease from entering the sewer system, reducing the risk of clogs and backups.

How Often Does a Grease Trap Need to Be Cleaned?

In general, it is recommended to clean a grease trap at least every 30 to 90 days. However, high-volume kitchens or those that produce a significant amount of FOG may require more frequent cleaning, such as every 15 to 30 days. Regular inspection of the grease trap is also important to determine the level of grease accumulation and plan a cleaning schedule.

What Happens If You Don't Clean a Grease Trap?

Failure to clean a grease trap regularly can lead to several issues, including foul odors, clogs in the drainage system, and potential violations of environmental regulations. With regular cleaning and maintenance, you can prevent these problems and extend the lifespan of the trap. You'll also improve the operation of the kitchen's wastewater management system.

What's the Difference between a Grease Trap and Grease Interceptor?

Grease traps are smaller in size and are installed underneath sinks or dishwashers to capture grease before it enters the drainage system. Grease interceptors, on the other hand, are larger in size and are usually installed outside the building, underground, or in a basement. They are designed to handle a higher volume of grease and solid waste.

By knowing how grease traps function, businesses can implement proper maintenance practices to ensure their effective operation. Regular maintenance, such as grease trap cleaning and inspection, helps prevent blockages and keeps the trap working as it should.