Have you ever wondered why the electric plug on your commercial equipment is more complicated than the plugs you use at home? Commercial plugs typically feature more complex configurations so that the right equipment can be matched to the right outlet. Without these special configurations, the wrong plug could be easily inserted into a mismatched outlet. This could lead to the equipment not working properly, or in the worst case, it could cause a fire hazard. That's why electrical plugs and outlets are designed to keep you and your business safe. Keep reading to learn more about the basics of electric plugs and what types are the most common in small businesses.

Differences between Commercial and Residential Plugs

When it comes to electrical plugs and outlets, the distinction between commercial and residential applications is crucial. Commercial electrical plugs are designed to meet the demands of heavy-duty equipment and high-power consumption commonly found in commercial settings. Attempting to plug in commercial equipment to an outlet that isn't rated for the right voltage could result in frequent tripping of circuit breakers, power outages, and damage to both the equipment and the electrical system. This is why it's not recommended to install heavy equipment in a home. Here are some key differences between commercial and residential plugs and outlets:

- Voltage and Amperage Ratings: Commercial electrical plugs are typically rated for higher voltages and amperages compared to their residential counterparts. This is essential for accommodating the power requirements of commercial equipment and machinery that operate on higher voltage systems.

- Durability and Construction: Commercial plugs and outlets are built to withstand frequent use and harsh environments. They are constructed with heavy-duty materials such as impact-resistant plastics and corrosion-resistant metals to ensure longevity and safety in commercial settings.

- Configuration and Compatibility: Commercial plugs often feature unique configurations to prevent accidental connections to incompatible devices. They may also incorporate locking mechanisms to secure the connection and prevent accidental disconnection during operation.

- Regulatory Compliance: Commercial electrical plugs and outlets must adhere to specific industry regulations and standards to ensure safety and compatibility with commercial electrical systems. Compliance with codes such as the National Electrical Code (NEC) is essential for maintaining a safe working environment.

What Is NEMA?

NEMA, which stands for the National Electrical Manufacturers Association, is an organization that sets standards for electrical products in the United States. These standards cover a wide range of electrical components, including electrical plugs, receptacles, connectors, and enclosures. The primary goal of NEMA is to make sure that electrical products are safe, reliable, and compatible with each other.

NEMA standards help manufacturers produce products that meet specific criteria for performance, safety, and design. When it comes to electrical plugs, NEMA standards specify the configuration, voltage rating, current capacity, and other important characteristics that ensure proper functionality and compatibility with electrical systems.

How to Read NEMA Numbers

The numbers and letters in a NEMA plug indicate specific characteristics and features that help users identify the type and capabilities of the plug. Here is what the numbers and letters in a NEMA plug mean:

- Voltage Rating: The first number of the NEMA designation indicates the maximum voltage the plug can safely handle. Commercial plugs that begin with 5 are rated for 125V, and plugs that begin with 6 are rated for 250V. If the plug starts with 14, it's rated for 125/250V. There are many other ratings but these are some of the most common.

- Amperage Rating: The amperage rating of a NEMA plug is denoted by the two numbers after the dash. These numbers represent the maximum amperage the plug can handle under normal operating conditions. For example, a NEMA 5-15 plug has a maximum amperage rating of 15 amps.

- Twist Locking Feature: Some NEMA plugs have a twist-locking feature denoted by an "L" in the designation. Twist-lock plugs require a twisting motion to secure them in place, providing a more secure connection compared to standard plugs. The NEMA code for a locking plug or receptacle will always begin with "L".

- Plug or Receptacle: The end of the plug name contains a "P" to indicate plug or an "R" to indicate receptacle.

Types of Plugs

There are many configurations of commercial electric plugs, which can be confusing at times. The reason for this is so that the right electrical equipment is used with the correct outlet. It's a safety feature that prevents you from plugging a cord into an outlet that can't support the amps and volts of the appliance. These are some of the most common electrical plug configurations you will find used in small businesses:

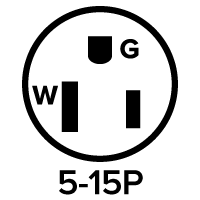

NEMA 5-15

5-15 plugs are the standard three-prong plugs that you see in most commercial settings. They have two flat prongs for the hot and neutral wires and a round prong for the ground wire. These plugs are rated for 15 amps and 125 volts, making them suitable for a wide range of applications such as powering computers, office equipment, and small appliances.

You'll notice that one blade is larger than the other, which is meant to prevent the 5-15 from being inserted incorrectly. The large blade is the neutral wire, and the small blade is the hot wire.

- Max Amperage: 15 amps

- Max Voltage: 125 volts

- Blades: Two vertical blades and one grounding pin

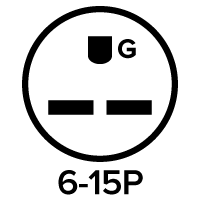

NEMA 6-15

NEMA 6-15 plugs are also three-prong plugs but are designed for higher voltage applications. They have two flat prongs for the hot wires and a round prong for the ground wire. These plugs are rated for 15 amps and 250 volts, making them ideal for powering larger equipment like industrial machinery and power tools.

The NEMA 6-15 plug is commonly used in commercial kitchens for powering heavy-duty equipment such as commercial ovens, mixers, and grills that require higher voltage levels to operate efficiently. Industrial settings, such as manufacturing plants and workshops, also rely on the NEMA 6-15 plug to provide power to machinery and equipment that demand 240 volts for optimal performance.

- Max Amperage: 15 amps

- Max Voltage: 250 volts

- Blades: Two horizontal blades and one grounding pin

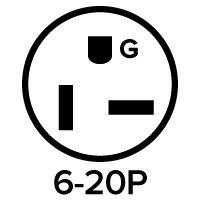

NEMA 6-20

The NEMA 6-20 plug is designed for higher power applications, with a maximum voltage rating of 250V and a maximum current rating of 20 amps. You can differentiate a 6-20 plug and receptacle from a 6-15 by the blades. The 6-20 plug has one verticle and one horizontal blade instead of two horizontal blades.

This plug is commonly used for larger equipment such as industrial machinery, air conditioners, and commercial kitchen appliances. Industrial settings, such as manufacturing plants and workshops, also rely on the NEMA 6-15 plug to provide power to machinery and equipment that demand 240 volts for optimal performance.

- Max Amperage: 20 amps

- Max Voltage: 250 volts

- Blades: One horizontal blade, one vertical blade, and one grounding pin

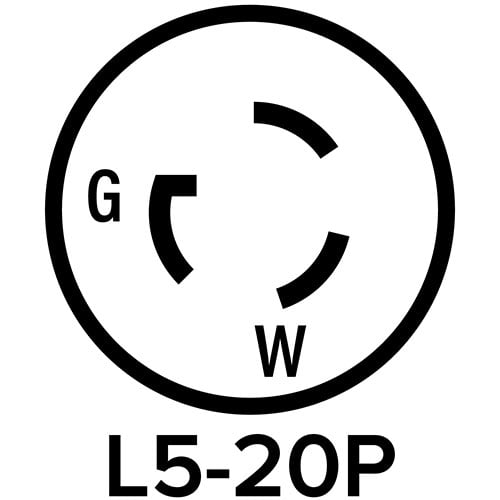

NEMA L5-20

NEMA L5-20 plugs are commonly used in commercial and industrial settings to provide a reliable power connection for equipment and machinery. The NEMA L5-20 plug features a two-pole, three-wire configuration, with a grounding pin that ensures safe and secure electrical connections. This particular plug is designed to deliver a maximum of 125 volts of power.

One key difference between the NEMA L5-20 plug and other NEMA plugs is its unique locking mechanism. The NEMA L5-20 plug is equipped with a twist-lock design that ensures a secure connection, reducing the risk of accidental disconnection that can lead to equipment damage or potential safety hazards. This feature makes the NEMA L5-20 plug ideal for environments where vibrations or movement may be present, such as construction sites or manufacturing facilities.

- Max Amperage: 20 amps

- Max Voltage: 125 volts

- Blades: Two curved blades and a curved grounding pin

NEMA L5-30

NEMA L5-30 plugs are twist-lock plugs with three prongs - two hot prongs and a ground prong. They are rated for 30 amps and 125 volts, making them suitable for high-power equipment such as generators, industrial lighting, and portable air conditioners.

One key difference between the NEMA L5-30 plug and the NEMA L5-20 plug is the amperage rating. While the L5-30 plug can handle up to 30 amps of current, the 5-20 plug is rated for 20 amps. This means that the L5-30 plug can deliver more power, making it ideal for heavy-duty machinery and equipment that require a higher electrical load. The grounding pin is located on the opposite side so that these plugs can't be mixed up.

- Max Amperage: 30 amps

- Max Voltage: 125 volts

- Blades: Two curved blades and a curved grounding pin

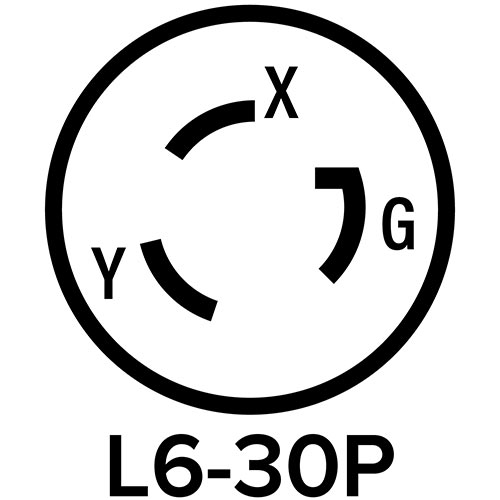

NEMA L6-30

NEMA L6-30 plugs are twist-lock plugs similar to L5-30 plugs but are rated for 250 volts and 30 amps. They can be recognized by two hot prongs and a ground prong. The configuration looks similar on these two plugs, but the blades are different lengths so that they cannot be mixed up.

You'll see this locking plug used for servers and critical infrastructure components that require a stable and secure power source to ensure uninterrupted operation. The NEMA L6-30 plug provides the necessary power delivery to keep these systems up and running without any interruptions.

- Max Amperage: 30 amps

- Max Voltage: 250 volts

- Blades: Two curved blades and a curved grounding pin

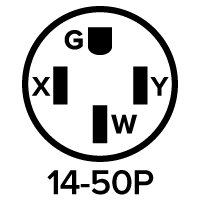

NEMA 14-50

This plug features four prongs - two hot, one neutral, and one ground. It's designed to handle a maximum voltage of 250V and a maximum current of 50 amps. The NEMA 14-50 plug is known for its robust construction and ability to deliver a high level of power, making it suitable for heavy-duty applications.

What sets the NEMA 14-50 plug apart from other plugs is its high amperage rating and compatibility with high-voltage systems. This plug is specifically designed to handle the demands of power-hungry appliances and equipment, making it a popular choice for industrial and commercial applications. Its standardized design also ensures that it can be easily installed and used across different settings, providing a versatile solution for powering a wide range of devices.

- Max Amperage: 50 amps

- Max Voltage: 250 volts

- Blades: Three vertical blades and one grounding pin

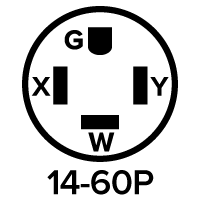

NEMA 14-60

The NEMA 14-60 plug is a specific type of electrical plug that is commonly used in commercial and industrial settings. This plug features four prongs, with two hot wires, a neutral wire, and a ground wire, making it suitable for high-power applications. The NEMA 14-60 plug is designed to handle a voltage of 250 volts and a current of up to 60 amps, making it ideal for appliances and equipment that require a substantial amount of electrical power.

One of the key uses of the NEMA 14-60 plug is in commercial kitchens, where heavy-duty cooking equipment such as commercial ovens and ranges are commonly powered by this type of plug. The high amperage and voltage capacity of the NEMA 14-60 plug make it well-suited for powering these energy-intensive appliances, ensuring they operate efficiently and safely.

- Max Amperage: 60 amps

- Max Voltage: 250 volts

- Blades: Two vertical blades, one horizontal blade, and one grounding pin

What Are the Parts of an Electric Plug?

The design of an electric plug ensures compatibility between devices and outlets, making it easier to connect equipment across different locations and industries. All of the parts on the plug and receptacle have a purpose:

- Prongs or Blades: The blades are the metal pieces on a plug that make physical contact with the outlet. These blades are designed to fit securely into the corresponding slots in the outlet.

- Grounding Pin: Most commercial plugs feature a third prong, known as the ground pin. This pin contains the ground wire, which helps prevent electrical shocks by providing a path for excess electricity to flow safely into the ground.

- Hot Wire (Line): The hot wire, also known as the line wire, carries the electrical current from the power source to the appliance or equipment. This wire is responsible for providing power to the device. Hot wires are designated by the letters "X", "Y", or "Z" on a plug and receptacle.

- Neutral Wire: The neutral wire is designated by "W" on plug and receptacle configurations. It completes the electrical circuit by providing a return path for the current to flow back to the power source. It carries the current away from the appliance back to the electrical panel.

- Blade Orientation: NEMA plugs have different blade orientations to prevent incorrect insertion into outlets, ensuring a secure and safe connection. The blades are typically arranged in a specific configuration to match the corresponding outlet receptacles.

- Polarization: Some NEMA plugs feature polarization, where one blade is wider than the other to ensure proper alignment with the outlet. This prevents reverse polarity connections and enhances safety by ensuring the correct flow of electricity.

- Locking Mechanism: Certain commercial plugs are equipped with a locking mechanism that secures the plug in the outlet, preventing accidental disconnection. This feature is especially useful in high-traffic areas or where vibration may loosen the connection.

Locking vs Nonlocking Plugs

Non-locking NEMA plugs, often referred to as straight-blade plugs, are designed for standard electrical outlets. These plugs feature two flat parallel blades and a grounding pin, making them easy to insert into and remove from receptacles. Non-locking plugs are commonly used for everyday appliances and equipment that do not require a secure connection.

Locking NEMA plugs are specifically designed to provide a secure and reliable connection in environments where vibration or movement may cause traditional plugs to become loose. Locking plugs feature a twist-lock design that requires the plug to be rotated and locked into place for a secure connection. This design prevents accidental disconnection and ensures continuous power supply, making locking plugs ideal for heavy-duty equipment, machinery, and outdoor applications.

Two Prong vs Three Prong Plugs

Two-pronged plugs, also known as ungrounded plugs, have two metal prongs that are inserted into the outlet. These plugs are commonly found on older electrical devices and appliances. They are designed to carry electrical current from the outlet to the device without providing a grounding connection. While two-pronged plugs are still in use, they are considered less safe than three-pronged plugs because they lack the added protection of a grounding wire.

On the other hand, three-pronged plugs, also known as grounded plugs, have two power prongs and one grounding prong. The third prong serves as a safety feature by providing a path for excess electrical current to be safely redirected to the ground, reducing the risk of electrical shock or fire. Most modern electrical appliances and equipment are designed to use three-pronged plugs to ensure safe and reliable operation.

NEMA plugs and receptacles are essential components in maintaining electrical safety and compliance in commercial environments. The unique plug configurations keep the right equipment paired with the appropriate receptacles, preventing tripped circuit breakers, risk of electric shocks, and damage to your property.