Warehouse Equipment & Tools

Stock up on Industrial Tools with Our Warehouse Supplies

Material Handling Equipment

Shop 27 Categories

Use material handling equipment to maneuver shipments and supplies throughout your warehouse with ease.

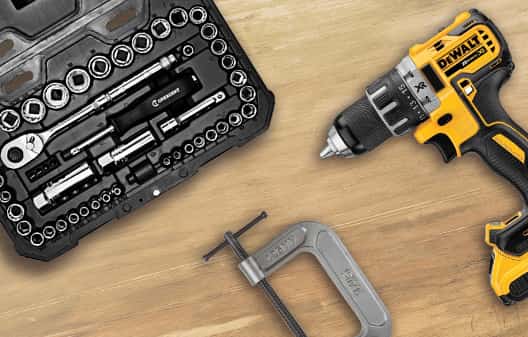

Maintenance Tools

Shop 22 Categories

For whatever facility issues you’re experiencing, use maintenance tools to fix the problem quickly.

Loading Dock Equipment

Shop 7 Categories

Utilize loading dock equipment to handle incoming and outgoing shipments efficiently.

Drum Handling Equipment

Shop 5 Categories

Given the size and weight of drums, using drum handling equipment allows you to move them easily.

Generators and Portable Power Stations

Shop 115 Products

Commercial generators keep your warehouse safe and functioning if your power goes out during a storm.

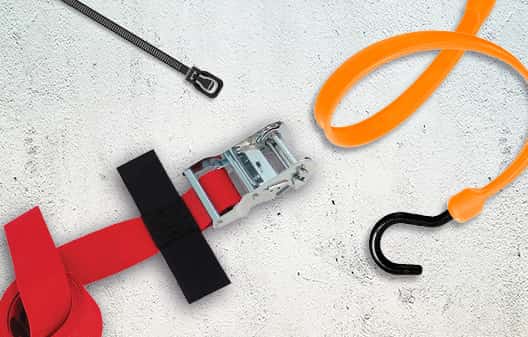

Strapping Supplies

Shop 3 Categories

Use load securement and strapping supplies to safely transport pallets and shipments.

Industrial Fans

Shop 210 Products

Keep your warehouse cool even on hot summer days by increasing airflow with industrial fans.

Inventory Management Equipment

Shop 5 Categories

Understanding your inventory is critical to success, so use inventory management tools to keep everything organized.

Top Products

Other Industrial Supplies

Safely Increase Your Productivity with Industrial Warehouse Equipment

Stock up on industrial warehouse supplies to create a productive workflow in your warehouse. These warehouse supplies not only reduce the effort to move the stock in your space, they also help prevent injuries caused by strain. Ensure that your warehouse is safe and efficient by choosing from our wide selection of tools and equipment.