Vollrath 40952 12" Heavy Duty Meat Slicer with Safe Blade Removal System - 1/2 hp

Item number Item #: 92240952MFR number MFR #: 40952

Item number Item #: 92240952MFR number MFR #: 40952

Works With

$2,435.56/Each

Login or enter your email to be instantly sent the price!

Start a Live Chat with a Customer Service rep to receive the price!

Mon-Thu 8AM-8PM EST · Fri 8AM-6PM EST · Sat 9AM-4PM EST

Earn up to $73.07 back (7,307 points)with a Webstaurant Rewards Visa® Credit Card

Quick Shipping

Usually ships in 1 business day

Product Overview

- Non-stick coating on gauge plate for easier cleanup

- Built-in sharpener

- 13/16" maximum slice thickness

- 11 1/8" x 7 5/8" cutting capacity

- 3" of clearance between back of blade and motor for easy cleaning

Shipping Restrictions

This item cannot ship to MN

UPC Code:400010678075

Works With

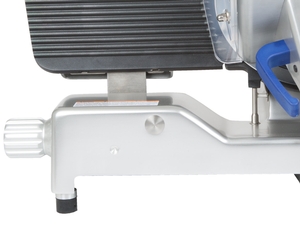

This Vollrath 40952 12" manual gravity feed slicer features a rugged design that makes it ideal for higher-volume operations.

Featuring a compact design that makes the most of your available work space, this slicer is great for slicing cheese and processed meat continuously throughout the day. It allows you to achieve precise and consistent slices while saving money by processing whole meats and cheeses yourself! Operation couldn't be any simpler thanks to a 35 degree gravity feed that maximizes productivity by reducing operator fatigue and discomfort.

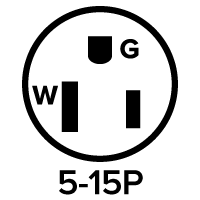

5-15P

This unit comes with a NEMA 5-15P plug.

Imported from Italy

This item is imported from Italy.

UL Certified

This product is certified to applicable standards and requirements by UL Solutions.

Built-In Sharpener

For convenient sharpening, this unit comes equipped with a built-in sharpening assembly. By keeping your slicer's blade sharp, you can ensure easier and faster slicing.

Exclusive Non-Stick Coating

The gauge plate is covered in a proprietary non-stick coating that reduces drag and ensures ease of cleaning.

13/16" Maximum Slice Thickness

The slice size of this model is adjustable up to 13/16" thick. This means you can slice thin vegetables and pepperoni or thick ham to top off signature pizzas or add to deli salads. To adjust the slice size, this unit has a solid aluminum adjustment knob for greater durability.

Removable Blade and Carriage

When it's time to clean up at the end of the day, the carriage from this unit can be easily removed so that you can access all of the components for thorough cleaning. Plus, this slicer comes with a removable blade and a safe blade removal tool so there is no need to worry about cleaning the blade in place.

Aluminum Body

The body of this slicer is made of durable anodized aluminum for durability, easy maintenance, and added safety.

1/2 hp Motor

This slicer has a heavy-duty 1/2 hp motor that is perfect for slicing continuously throughout the day. This slicer can even cut cheese along with deli meats or vegetables.

Questions & Answers

Looking For Specific Info? Get quick answers to product questions with our AI-powered search.

Compare to Other Products

Price

Width

Depth

Maximum Product Width

Maximum Product Height

Voltage

Blade Size

Horsepower

Slice Size

Slices Cheese

- Item #: 92240952Vollrath 40952 12" Heavy Duty Meat Slicer with Safe Blade Removal System - 1/2 hp

Price

Price:$2,435.56/Each

- Width: Width27 15/16 Inches

- Depth: Depth22 9/16 Inches

- -specification unavailable

- -specification unavailable

- Voltage: Voltage120 Volts

- Blade Size: Blade Size12 Inches

- Horsepower: Horsepower1/2 hp

- -specification unavailable

- Slices Cheese: Slices CheeseCan Slice Cheese

- Item #: 177sl512Avantco SL512 12" Manual Gravity Feed Meat Slicer - 1/2 hp

Price

Price:$739.00/Each

- Width: Width19 Inches

- Depth: Depth25 Inches

- Maximum Product Width: Maximum Product Width11 Inches

- Maximum Product Height: Maximum Product Height8 Inches

- Voltage: Voltage120 Volts

- Blade Size: Blade Size12 Inches

- Horsepower: Horsepower1/2 hp

- -specification unavailable

- Slices Cheese: Slices CheeseCan Slice Cheese

- Item #: 377g12Globe G12 12" Manual Gravity Feed Slicer - 1/2 hp

Price

Price:$1,852.00/Each

- Width: Width22 1/4 Inches

- Depth: Depth19 1/4 Inches

- Maximum Product Width: Maximum Product Width10 Inches

- Maximum Product Height: Maximum Product Height10 1/4 Inches

- Voltage: Voltage115 Volts

- Blade Size: Blade Size12 Inches

- Horsepower: Horsepower1/2 hp

- Slice Size: Slice Size9/16 Inch

- Slices Cheese: Slices CheeseCan Slice Cheese

- Item #: 377g12aGlobe G12A 12" Automatic Slicer - 1/2 hp

Price

Price:$3,995.00/Each

- Width: Width24 5/8 Inches

- Depth: Depth20 1/8 Inches

- Maximum Product Width: Maximum Product Width10 Inches

- Maximum Product Height: Maximum Product Height8 1/4 Inches

- Voltage: Voltage115 Volts

- Blade Size: Blade Size12 Inches

- Horsepower: Horsepower1/2 hp

- Slice Size: Slice Size9/16 Inch

- Slices Cheese: Slices CheeseCan Slice Cheese

- Width:

- 27 15/16 Inches

- Depth:

- 22 9/16 Inches

- Height:

- 22 9/16 Inches

Please check the Compatibility resource for information on items that work with this product.

This Item Ships via Common Carrier. For more information and tips to help your delivery go smoothly, click here.

Need Parts & Accessories?

Show replacement parts and accessories for Vollrath 40952 today!

Find Parts for this ItemResources and Downloads for

Vollrath 40952

Specsheet

Opens in new tab

Manual

Opens in new tab

Warranty

Opens in new tab

Cleaning Instructions

Opens in new tab

Diagram

Opens in new tab

Brochure

Opens in new tab

Compatibility

Opens in new tabA PDF viewer is required to view this product's information. Download Adobe Acrobat softwareOpens in new tab

Warranty Info

RESIDENTIAL USERS: Vendor assumes no liability for parts or labor coverage for component failure or other damages resulting from installation in non-commercial or residential applications. Your warranty will be voided if installed in non-commercial or residential applications.

Vollrath 40952 Specs

- Quantity

- 1/Each

- Shipping Weight

- 98.6 lb.

- Width

- 27 15/16 Inches

- Depth

- 22 9/16 Inches

- Height

- 22 9/16 Inches

- Power Cord Length

- 76 Inches

- Amps

- 2 Amps

- Hertz

- 60 Hz

- Phase

- 1 Phase

- Voltage

- 120 Volts

- Wattage

- 240 Watts

- Blade Size

- 12 Inches

- Horsepower

- 1/2 hp

- Installation Type

- Countertop

- Maximum Slice Size

- 13/16 Inch

- Operation

- Manual

- Plug Type

- NEMA 5-15P

- Power Type

- Electric

- RPM

- 285 RPM

- Slicer Usage

- Premium

- Slices Cheese

- Can Slice Cheese

- Type

- Meat Slicers

Equivalent Items

- Vollrath 40904 (Formerly)