$1,758.15/Each

Ships free with PlusLogin or enter your email to be instantly sent the price!

Start a Live Chat with a Customer Service rep to receive the price!

Mon - Thur: 5am - 12am EST

Fri: 5am - 8pm EST

Sat & Sun: 9am - 4pm EST.

Earn up to $52.74 back (5,274 points)with a Webstaurant Rewards Visa® Credit Card

Product Overview

- One clear, high visibility 6 liter Bowl

- Magnetic drive system is reliable, durable, and easier to clean with no gears and less parts

- Intuitive controls, including single on/off switch, product selector switch, dial speed control and

- Large freezing surface and compressor reduces freeze down times and promotes efficient operation

- Ease of maintenance with less wear parts, such as o-rings and spigot bodies

Works With"Works With" items are guaranteed to work with the item you are viewing, such as lids that will fit a cup or casters that will fit a piece of equipment. If an item is not listed in this section, we do not guarantee that it will work with the product you are viewing and do not recommend that you purchase them for use together.

$36.99/Case

$57.29/Case

$819.00/Each

$639.00/Each

$46.99/Case

$84.99/Case

$28.49/Case

- Quantity

- 1/Each

- Shipping Weight

- 96 lb.

- Width

- 7 3/4 Inches

- Depth

- 19 1/2 Inches

- Height

- 23 3/4 Inches

- Amps

- 4 Amps

- Hertz

- 60 Hertz

- Phase

- 1 Phase

- Voltage

- 120 Volts

- Wattage

- 480 Watts

- Capacity

- 1.6 Gallons

- Capacity per Bowl

- 1.6 Gallons

- Capacity per Compartment

- 1.6 Gallons

- Features

- NSF Listed

- Number of Bowls

- Single

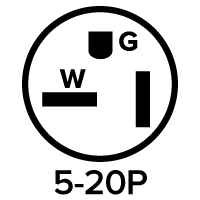

- Plug Type

- NEMA 5-20P

- Product Type

- Beverage Dispensers Countertop Equipment

- Style

- Standard Pourover

- Type

- Granita / Slushy Machines

Customer questions about this product

About how long does it take for drink mix to freeze in a slushy machine?

Can I add alcohol in my drinks with this slushy machine?

Vollrath VCBA118-37 Details

Cool your customers off with a delicious frozen beverage and do so in style with the Vollrath VCBA118-37 single 1.6 gallon frozen beverage machine! Whether you're adding it to your restaurant, convenience store, or bar, this machine is exactly what you need to streamline and boost your frozen beverage service. Capable of serving anything from granitas and smoothies to iced or frozen coffee/tea and frozen cocktails, this unit is sure to substantially expand your beverage menu.

A single 6 liter bowl is designed with a clear, highly visible casing so your beverages can be clearly identified. Alternatively, you can upgrade to a double walled bowl (sold separately) to eliminate the chance of condensation build-up. An interior bowl light illuminates your beverages, thus showcasing their vibrant colors and helping them sell themselves. Easy-to-use controls are both intuitive and customizable enough to offer an array of different drink styles. A frozen beverage mode will allow you to make adjustments to temperature, while the granita setting lets you adjust the consistency until it is ideal.

A magnetic drive system is reliable, durable, and easy to maintain. As opposed to a mechanical drive system there is much less wear on the parts of a magnetically driven motor, which will give your machine more longevity and will result in less service calls. The large freezing surface and properly sized compressor reduce freeze down times and promotes efficient operation. This means that when you turn on the machine at the start of your businesses operation, there is much less waiting time for your beverages to reach optimal temperature. When it comes time for cleanup, the gasketless spigot will make cleaning and sanitation much easier than a traditional gasketed model. This unit requires a 120V electrical connection for operation.

Overall Dimensions:

Width: 7 3/4"

depth: 19 1/2"

Height: 23 3/4"

Capacity: 1.6 gallon (6 liters)

This Item Ships via Common Carrier. For more information and tips to help your delivery go smoothly, click here.

NSF Listed

This item has been certified by NSF International to meet applicable product standards on public safety, health, and / or the environment.

ETL, US & Canada

This product has been certified by ETL, a division of the Intertek Group, to meet applicable electrical product safety standards required for use in the United States and Canada.

5-20P

This unit comes with a NEMA 5-20P plug.

Need Parts & Accessories?

Show replacement parts and accessories for Vollrath VCBA118-37 today!

Resources and Downloads for

Vollrath VCBA118-37

A PDF viewer is required to view this product's information. Download Adobe Acrobat software

Other Products from this Line

Customer Reviews

1 reviews rated this 5 out of 5 stars.

0 reviews rated this 4 out of 5 stars.

0 reviews rated this 3 out of 5 stars.

0 reviews rated this 2 out of 5 stars.

0 reviews rated this 1 out of 5 stars.

Frequently Mentioned

- easy

- beverage

- charm

- clean

- frozen

- gallon

- happy

- machine

- margaritas

- more