Hobart FP100-1 Continuous Feed Food Processor - 1/3 hp

Item number Item #: 425fp1001MFR number MFR #: FP100-1

Item number Item #: 425fp1001MFR number MFR #: FP100-1

Works WithView All Items

$3,589.60/Each

Contact us for details

Call 717-392-7472Mon-Fri 8AM-6PM EST

Earn up to $107.69 back (10,769 points)with a Webstaurant Rewards Visa® Credit Card

Quick Shipping

Usually ships in 1 business day

Product Overview

- Occupies minimal counter space

- 120/60/1 electrical connection

- 11 lb. per minute production capability

- 420 RPM plate speed

- Easy-to-operate ON-OFF switches

- Ergonomic angled hopper

- Continuously cuts long products to eliminate precutting

UPC Code:fp100-1

Works With

View All ItemsThe Hobart FP100-1 continuous feed food processor is perfect when you're in need of a food processing workhorse.

This food processor is ideal for quickly slicing or shredding fresh vegetables, fruits, potatoes, and even cheese and herbs! It is designed for simple, ergonomic use with a 50 degree angled front for operator convenience and rapid product loading. Plus, this model takes up minimal counter space with its small 8 13/16" wide footprint but still manages to process up to 11 lb. of product per minute-that's 660 lb. per hour!

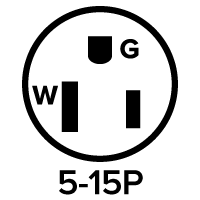

5-15P

This unit comes with a NEMA 5-15P plug.

NSF Certified

This item is certified by NSF to applicable standards.

UL Certified

This product is certified to applicable standards and requirements by UL Solutions.

Large Feed Hopper

A large, half size feed hopper supports processing plates (sold separately) for a wide variety of products, while permitting continuous cutting of long products. Never precut again!

Simple On / Off Switch

With its simple on-off switch you can be sure that this food processor is an easy-to-use, efficient product for your commercial kitchen. Even your newest employees can use this food processor with minimal training.

Lid Interlock

An interlocking switch keeps the machine from operating when the lid and pusher plate aren't correctly in place.

420 RPM Plate Speed

The set 420 RPM plate speed quickly and easily cuts, chops, slices, and dices whatever you need to process to help your commercial kitchen reach optimum productivity.

Powerful 1/3 hp Motor

The Hobart FP100-1 continuous feed food processor features a powerful 1/3 hp, 3.5 amp motor with overload protection.

Questions & Answers

Looking For Specific Info? Get quick answers to product questions with our AI-powered search.

- Width:

- 8 13/16 Inches

- Depth:

- 16 11/16 Inches

- Height:

- 19 1/2 Inches

Need Parts & Accessories?

Show replacement parts and accessories for Hobart FP100-1 today!

Find Parts for this ItemResources and Downloads for

Hobart FP100-1

Specsheet

Opens in new tab

Manual

Opens in new tab

Warranty

Opens in new tab

Cutting Tool Guide

Opens in new tab

Hobart Food Processor Guide

Opens in new tab

Capacity Guide

Opens in new tab

Diagram

Opens in new tabA PDF viewer is required to view this product's information. Download Adobe Acrobat softwareOpens in new tab

Warranty Info

RESIDENTIAL USERS: Vendor assumes no liability for parts or labor coverage for component failure or other damages resulting from installation in non-commercial or residential applications. Your warranty will be voided if installed in non-commercial or residential applications.

Hobart FP100-1 Specs

- Quantity

- 1/Each

- Shipping Weight

- 36.74 lb.

- Width

- 8 13/16 Inches

- Depth

- 16 11/16 Inches

- Height

- 19 1/2 Inches

- Amps

- 3.5 Amps

- Hertz

- 60 Hz

- Phase

- 1 Phase

- Voltage

- 120 Volts

- Wattage

- 420 Watts

- Features

- NSF Certified

- Hopper Style

- Half Moon

- Horsepower

- 1/3 hp

- Number of Discs

- None

- Output

- 660 lb. per Hour

- Plug Type

- NEMA 5-15P

- Power Type

- Electric

- RPM

- 420 RPM

- Speeds

- 1 Speed

- Type

- Continuous Feed Processors