$4,163.50/Each

Ships free with PlusEarn up to $124.91 back (12,491 points)with a Webstaurant Rewards Visa® Credit Card

Installation Services

Check if installation is currently available for your area.

Product Overview

- Manual fill dispenser - does not produce ice

- 110 lb. storage capacity

- Lever dispensing system

- Agion antimicrobial technology

- Dispenses Chewblet ice and cube ice up to 1" square

- 115V, 800W

Works With"Works With" items are guaranteed to work with the item you are viewing, such as lids that will fit a cup or casters that will fit a piece of equipment. If an item is not listed in this section, we do not guarantee that it will work with the product you are viewing and do not recommend that you purchase them for use together.

- Quantity

- 1/Each

- Shipping Weight

- 119 lb.

- Width

- 25 Inches

- Depth

- 28 1/4 Inches

- Height

- 34 3/4 Inches

- Height to Dispenser

- 7 3/4 Inches

- Amps

- 4 Amps

- Hertz

- 60 Hertz

- Phase

- 1 Phase

- Voltage

- 115 Volts

- Bin Storage Capacity

- 110 lb.

- Dispenser Style

- Lever

- Features

- Made in America NSF Listed

- Ice Type

- Chewblet Full Size Cubes

- Installation Type

- Countertop

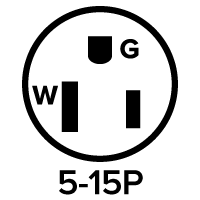

- Plug Type

- NEMA 5-15P

- Type

- Manual Fill Ice Dispensers

Customer questions about this product

What is a "manual fill" ice dispenser?

A manual fill dispenser doesn't actually make ice, so it will need to be manually filled with ice from a remote location. A hopper on top of the dispenser holds the ice for dispensing. An ice machine cannot be mounted on top for automatic filling, like a modular dispenser.

This is a great option if you already have an operating ice machine and bin elsewhere in your establishment and are looking to add a new dispensing option without the added cost of purchasing another ice machine.

Follett Corporation 110CM-NI-LI Details

Provide patients at your healthcare facility or residents at your retirement community with ice for drinks, ice packs and more with this Follett 110CM-NI-LI Symphony Plus ice dispenser! This manual-fill machine boasts a 110 lb. storage capacity and is capable of smoothly dispensing Chewblet ice and cube ice up to 1" square, while a one-hand lever operation makes dispensing a breeze!

Since this dispenser does not produce ice, it's perfect for facilities that already have an ice machine and bin in the kitchen, but want to allow patrons the convenience of dispensing their own ice. Simply fill the top-mounted hopper with up to 110 lb. of ice, enough to last through your busiest services!

This 110 lb. ice dispenser takes up minimal space on your countertop thanks to its compact footprint, while the dispenser itself is both attractive and built to last! The stainless steel exterior features a subtle accent trim and smooth contours for an aesthetically pleasing appearance that is complemented by a corrosion-resistant plastic drain pan and dispenser lid. Just as important, this ice dispenser incorporates Agion silver-based antimicrobial technology that provides protection of key components that come into contact with ice.

Overall Dimensions:

Left to Right: 25"

Front to Back: 28 1/4"

Height: 34 3/4"

Cup Clearance: 7 3/4"

This Item Ships via Common Carrier. For more information and tips to help your delivery go smoothly, click here.

Because this item is not stocked in our warehouse, processing, transit times and stock availability will vary. If you need your items by a certain date, please contact us prior to placing your order. Expedited shipping availability may vary. We cannot guarantee that this item can be cancelled off of the order or returned once it is placed.

ETL, US & Canada

This product has been certified by ETL, a division of the Intertek Group, to meet applicable electrical product safety standards required for use in the United States and Canada.

NSF Listed

This item has been certified by NSF International to meet applicable product standards on public safety, health, and / or the environment.

Made in America

This item was made in the United States of America.

5-15P

This unit comes with a NEMA 5-15P plug.

Need Parts & Accessories?

Show replacement parts and accessories for Follett Corporation 110CM-NI-LI today!

Resources and Downloads for

Follett Corporation 110CM-NI-LI

A PDF viewer is required to view this product's information. Download Adobe Acrobat software

Resources