PolyJohn SA1-1009 We'll Care III Yellow Wheelchair Accessible Portable Restroom - Assembled

Item number 621sa11009MFR number SA1-1009

Usually Ships in 5-6 Weeks from manufacturer

Lead times vary based on manufacturer stock

Product Overview

- Maximum ventilation to reduce smells

- Roomy and spacious interior is perfect for wheelchairs

- Handrails on all walls

- Zero barrier entry to easily roll wheelchairs inside

- 50 gallon capacity tank

UPC Code:400013069719

Works With

View All Items- Quantity

- 1/Each

- Shipping Weight

- 675 lb.

- Length

- 92 7/16 Inches

- Width

- 85 1/4 Inches

- Height

- 92 1/2 Inches

- Door Width

- 32 3/4 Inches

- Door Height

- 80 Inches

- Seat Height

- 19 Inches

- Assembly Options

- Fully Assembled

- Color

- Yellow

- Features

- Made in America Wheelchair Accessible

- Style

- ADA Compliant

- Tank Capacity

- 50 Gallons

- Type

- Portable Restrooms

PolyJohn SA1-1009 Details

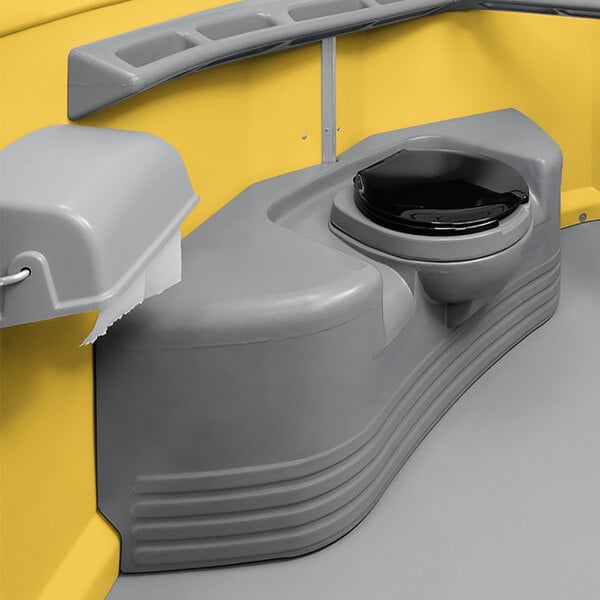

Designed to exceed the ADA portable toilet guidelines, this PolyJohn SA1-1009 We'll Care III yellow wheelchair accessible portable restroom is a highly popular, spacious, and praised portable restroom. This is the largest PolyJohn portable restroom. The interior is incredibly spacious and the door is oversized to accommodate all sizes of wheelchairs. Additionally, the floor access is at ground level and barrier free, making it easy to roll a wheelchair inside. Inside the restroom, there are handrails on all the walls. They are 33" off the floor and help make transitioning from a wheelchair to the restroom seat easy and safe. With its lightweight, compact, and sturdy design, this portable restroom is the perfect choice for concerts, fairs, or any other outdoor event. Additionally, the self-closing door has a very small gap at the bottom to help increase privacy while keeping debris and dirt out. There is even a male/female/handicap sign that is included for the door or side of the portable restroom. This portable restroom sets the standard for the sanitation industry especially for people with physical disability or mobility impairment.

Each portable restroom includes a ventilation pipe to keep odors and unpleasant smells minimized inside the portable restroom too. On the door, there is an occupancy signal latch that lets you know if the unit is currently in use. This portable restroom even has a place for decals so you can label them with your business's logo.

Easy to clean wheelchair accessible portable toilets are an essential addition to any outdoor event. The tough construction inside and out is ideal for commercial worksites too. Offer your guests the best with this PolyJohn We'll Care III wheel chair accessible unit. This item comes fully assembled.

PolyJohn sets the standard for the sanitation industry and is the leading manufacturer of portable restrooms. Their products are made for high traffic areas such as commercial worksites, festivals, and fairs. Most importantly, each PolyJohn is designed to be easy to clean and maintain. Regardless of where you need them, PolyJohn's products are built to withstand years of use.

Overall Dimensions:

Exterior Length: 92 7/16"

Exterior Width: 85 1/4"

Exterior Height: 92 1/2"

Door Frame Width: 32 3/4"

Door Frame Height: 80"

Interior Turning Circle: 60"

Seat Height: 19"

Holding Tank Capacity: 50 gallon

This Item Ships via Common Carrier. For more information and tips to help your delivery go smoothly, click here.

Because this item is not stocked in our warehouse, processing, transit times and stock availability will vary. If you need your items by a certain date, please contact us prior to placing your order. Expedited shipping availability may vary. We cannot guarantee that this item can be cancelled off of the order or returned once it is placed.

Made in America

This item was made in the United States of America.

Fully Assembled

This item arrives fully assembled, and requires no additional assembly prior to use.

Questions & Answers

Looking For Specific Info? Get quick answers to product questions with our AI-powered search.

Frequently Asked Questions From Customers

For commercial work sites, it is recommended to have 1 portable restroom for every 10 workers.

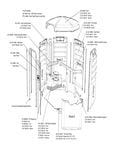

Resources and Downloads for PolyJohn SA1-1009

Manual

Opens in new tab

Warranty

Opens in new tab

Restroom and Sink Estimator

Opens in new tab

Diagram

Opens in new tab

Brochure

Opens in new tabA PDF viewer is required to view this product's information. Download Adobe Acrobat softwareOpens in new tab