Food Cans Buying Guide

Canned goods extend the shelf life of many food items without sacrificing nutritional value for a lower cost than fresh or frozen options. Unlike fresh produce that loses nutrients over time and frozen products that may lose nutrients through oxidation, canned foods are sealed at peak ripeness and retain their nutritional properties for extended periods. With advantages such as preserving food quality over time, extending product shelf life, and ensuring packaging safety, food cans play a crucial role in foodservice.

Shop All Canned Vegetables

Can Sizes Chart

Our can size chart provides a helpful breakdown of the different can size numbers and their equivalent weight or cup size. The measurements in ounces in this chart refer to what is in the can, not product yields from using the can. Some sizes can also vary by a few ounces depending on the specific product you purchase, so always read the label closely.

|

|

|

|---|---|---|

#1 | 11 oz. | 1 1/3 cups |

#1 tall | 16 oz. | 2 cups |

#1 square | 16 oz. | 2 cups |

#2 | 1 Ib. 4 oz. | 2 1/2 cups |

#2.5 | 1 Ib. 13 oz. | 3 1/2 cups |

#3 | 51 oz. | 4 cups |

#5 | 56 oz. | 7 cups |

#10 | 6 Ib. 6 oz. | 12 3/4 cups |

#300 | 14 - 16 oz. | 1 3/4 cups |

#303 | 16 - 17 oz. | 2 cups |

Reading Food Can Dimensions

Most recipes and can racks will specify a can size rather than a volume. Knowing the dimensions and capacities of the most common cans on the market is imperative when planning meals and evaluating storage space in the foodservice industry. Restaurants, cafeterias, daycare centers, and more rely on canned goods as a quick, economical way to serve patrons.

In the United States, packers measure metal cans before seaming. These dimensions are nominal and use a conventionalized method in which three-digit numbers express each dimension. Within each three-digit grouping, the first digit indicates the number of whole inches in a dimension. The second and third digits indicate the fractional inches as sixteenths of an inch.

The first three-digit number indicates the diameter measured across the outside of the chime on the seamed end. The second three-digit number indicates the overall height of the can.

- 303 x 406 means 3 3/16 x 4 6/16 inches

- 307 x 512 means 3 7/16 x 5 12/16 inches

- 603 x 700 means 6 3/16 x 7 inches

Types of Food Cans

From a manufacturing standpoint, food cans are assembled from two or three pieces of metal. Two-piece cans have fewer seams, which lessens the chance of compromising the integrity of the can. However, three-piece cans are easier to open and produce than two-piece cans.

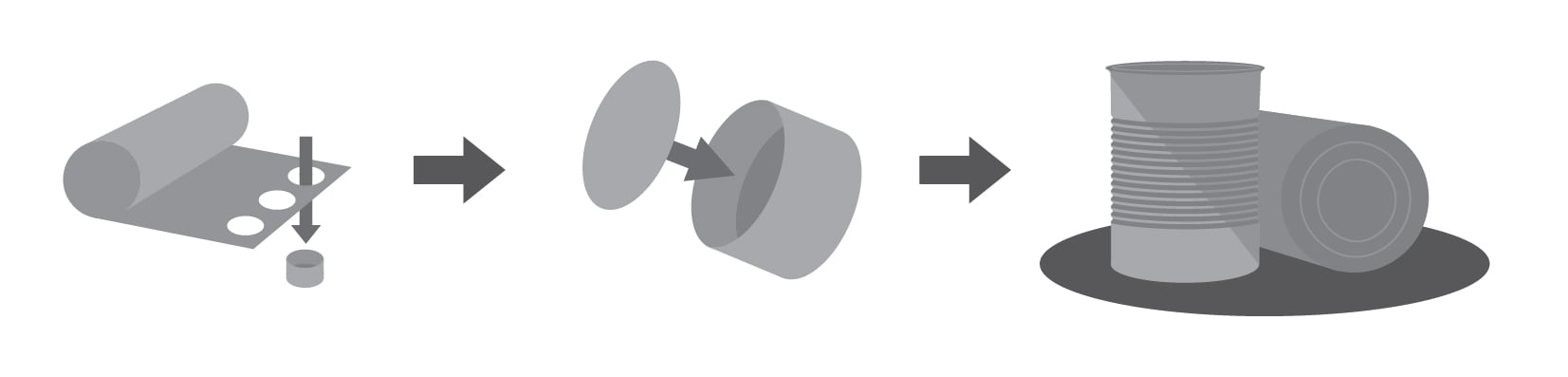

Two-Piece Metal Food Cans

Two-piece metal food cans feature a body integrated with a bottom lid and a lid with a lip. These cans are made using a drawing process in which a coil of coated rolled metal is fed into a press and formed into a cup-shaped object, complete with a flat, round bottom and cylindrical side walls. There are two types of two-piece cans based on the manufacturing process:

- Draw and Redraw Cans (DRD): The cups go through a second drawing phase, or the redraw, to achieve the final shape.

- Draw and Wall Ironing Cans (DWI): The cups go through a wall ironing phase that results in the cup walls being stretched and ironed to a predetermined height.

Whether the can is redrawn or ironed, the final step is to trim the cup into a finished container before filling and sealing the top lid via double seaming.

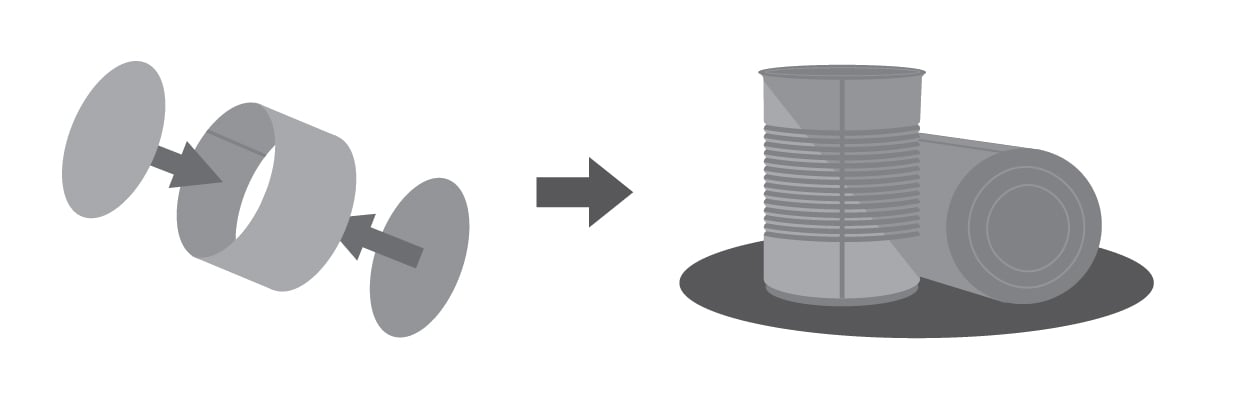

Three-Piece Metal Food Cans

Three-piece metal food cans feature a bottom lid, cylindrical body, and top lid. These cans are made with a rectangular, flat sheet of food-grade steel shaped into a cylinder and closed with a vertical side seam. The bottom end is then attached via "double seaming" to create a hermetic seal. Once filled, the can is closed at the top with a similar seal to the bottom. Depending on the manufacturer, three-piece cans are soldered or welded for assembly.

Food Can Materials

The most common materials used for food cans are steel, tin, aluminum, and paper, each offering unique benefits for commercial food storage. Each material has characteristics that make it suitable for different food products.

Steel

Steel is commonly used for food cans due to its durability and strength, but manufacturers will coat it in tin or aluminum to prevent corrosion. They provide excellent protection for food products, making them ideal for long-term storage and transportation. Additionally, steel cans are recyclable, making them a sustainable packaging option for businesses looking to reduce environmental impact.

Tin

Tin is often used as a coating for steel cans to prevent corrosion and enhance the shelf life of canned foods. Cans with tin coatings are suitable for acidic foods, as tin provides a barrier against interactions that could affect the taste or quality of the product. Due to these properties, tin cans are popular for canning fruits, vegetables, and acidic sauces.

Aluminum

Aluminum cans are light weight and resistant to corrosion, making them a popular choice for packaging beverages and food products. They are easily recyclable, with high recycling rates contributing to sustainable packaging practices. The flexibility of aluminum allows for creative packaging designs and shapes, making it an adaptable material for food cans.

Paper

Though less popular than metal, paperboard cans are an eco-friendly alternative that offers a sustainable packaging solution for environmentally conscious businesses. They are light weight and easily customizable, making them ideal for packaging dry goods, snacks, and confectionery products. The recyclability of paperboard cans further enhances their appeal as a sustainable packaging option in the food industry.

How to Dispose of Aluminum Cans

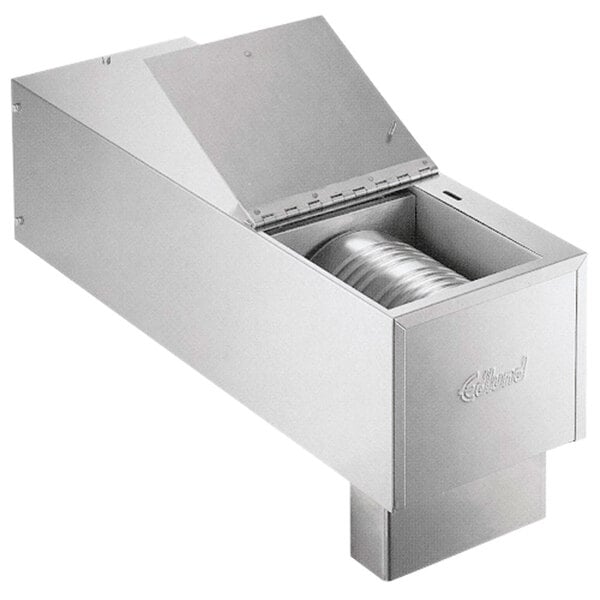

Once aluminum cans have served their purpose, it's important to dispose of them properly to minimize environmental impact and maximize recycling efforts. One efficient way to dispose of aluminum cans is by using a can crusher. These handy devices are designed to compress cans, making them easier to store and transport for recycling. Here's how you can effectively dispose of aluminum cans with a can crusher:

- Prepare the Can Crusher: Before using a can crusher, make sure it is properly set up and ready to use. Most can crushers are simple to operate and require minimal assembly.

- Insert the Can: Place an empty aluminum can into the opening of the can crusher. The can should be positioned with the opening facing down towards the crushing mechanism.

- Crush the Can: Lower the handle or press the button, depending on the type of can crusher you are using, to apply pressure and crush the can. The can crusher will compress the can, reducing its size significantly.

- Collect Crushed Cans: Once the can is crushed, remove it from the crusher and collect the crushed cans in a bin or bag. By compacting the cans, you can store more cans in a smaller space, making it easier to transport them for recycling.

- Recycle the Cans: After you have collected a sufficient amount of crushed cans, take them to a recycling center or drop-off location. Recycling aluminum cans helps conserve natural resources and reduces energy consumption compared to producing new cans from raw materials.

Related Resources

What Is FIFO?

When managing a commercial kitchen, implementing the FIFO method is essential. FIFO is an inventory control method in which the first items that come into your facility are the first to leave. This method helps reduce waste, maintain food quality, and improve efficiency in your kitchen operations. By following FIFO practices, you can ensure that you properly store your food, optimize your storeroom space , and create a streamlined inventory management system. What Does FIFO Stand For? FIFO is an acronym for "first in, first out." The FIFO method is all about storing and rotating stock to ensure items that have been there the longest are used or sold first. This term is commonly used in warehouses, distribution centers, and foodservice opera

Can Openers Guide

Because there are so many types of can openers, having one of the top can openers for the job can save you time and energy. Commercial can openers are broken down into three main categories. Manual can openers are great for lower-volume use. Electric can openers are a good choice for moderate-volume use. Crown punches are designed for consistent, high-volume usage.

Can Opener Reviews

Check out our can opener reviews to find the product that will complete your food prep area. These top can openers help you quickly and easily open cans of fruit, vegetables, filling, sauces, fish, and other cooking ingredients, so you can complete your signature dishes. Choose from hand-held and wall-mount units for light-duty applications, or purchase a table-mount option for more heavy-duty can opening. You can even find electric can openers that make opening cans even quicker. By using our can opener comparison to make your purchasing decision, you're sure to find the perfect product for your commercial kitchen.

- Topics 1357

- Industrial 55

- Troubleshooting Guides 21

- Restaurant Management 128

- Bar Management 56

- Catering Tips 36

- Bakery Management 42

- Food Trucks & Concessions 49

- Advertising & Marketing 37

- Eco-Friendly Tips 11

- Facility Layout & Design 42

- Coffee Shop Tips 28

- Installation & Maintenance 51

- Janitorial & Pest Control 30

- Safety & Sanitation 88

- Startup Tips 104

- Menu Design 10

- Kitchen & Cooking Tips 84

- Hospitality Management 24

- Pizza & Sandwich Shop Tips 36

- Smallwares 37

- Food Prep 89

- Tabletop Items 17

- Disposables 22

- Calculators & Tools 6

- Consumables 52

- Warewashing & Laundry 19

- Cooking Equipment 91

- Food Storage & Refrigeration 51

- Beverage Equipment 35

- Office Supplies 6

- Resource Type

- In-Depth Articles273

- Buying Guides298

- How-Tos95

- Product Reviews78