- Topics 1543

- Industrial 59

- Troubleshooting Guides 32

- Restaurant Management 142

- Bar Management 66

- Catering Tips 41

- Bakery Management 48

- Food Trucks & Concessions 47

- Advertising & Marketing 40

- Eco-Friendly Tips 11

- Facility Layout & Design 49

- Coffee Shop Tips 31

- Installation & Maintenance 60

- Janitorial & Pest Control 35

- Safety & Sanitation 112

- Startup Tips 111

- Menu Design 11

- Kitchen & Cooking Tips 104

- Hospitality Management 26

- Pizza & Sandwich Shop Tips 30

- Smallwares 40

- Food Prep 102

- Tabletop Items 20

- Disposables 26

- Calculators & Tools 8

- Consumables 71

- Warewashing & Laundry 22

- Cooking Equipment 101

- Food Storage & Refrigeration 54

- Beverage Equipment 39

- Office Supplies 5

Shop All Kitchen Knives

Use the following links to navigate and learn about the different types of knives:

The various types of kitchen knives are used for numerous tasks, and it can be difficult to know which knives are essential for your kitchen. Below are the 15 most commonly used kitchen knife types and what they are used for.

1. Chef Knife

The chef knife is the most versatile type of kitchen knife, making it a must-have item in every kitchen. Also called a cook's knife, a chef knife has a long, wide blade that tapers to a sharp point. This design allows it to rock back and forth quickly for fast mincing and chopping. They typically feature a straight edge to cut through foods smoothly in a few easy strokes. A chef knife's blade length ranges in size from 6" to 12”, with 8" being the most popular size.

What Is a Chef Knife Used For?

- Chopping herbs and nuts

- Dicing and slicing fruits, vegetables, and meats

- Mincing and crushing garlic

- Cutting through melons

2. Utility Knife

Utility knives are a mix between chef knives and paring knives. A utility knife's blade is longer than a paring knife and narrower than a chef knife to provide precision for cutting jobs where a chef knife may be too bulky to use and a paring knife too small. They can feature a serrated or straight edge to handle a wide variety of tasks. A utility knife's blade length ranges in size from 5" to 9”, with 6" being the most popular size.

What Is a Utility Knife Used For?

- Cutting small- to medium-sized fruits and vegetables

- Slicing through meats and bread

- Peeling citrus fruits

3. Cleaver

Cleavers easily break down meat, bones, and dense foods. They have a short, wide blade that resembles an ax with a straight edge that makes them useful for chopping and hacking with an up-and-down motion. There are 2 types of cleavers: meat cleavers, which are designed for raw meat prep, and vegetable cleavers, which have a thinner blade and are better suited for chopping vegetables and slicing through fish. A cleaver's blade length ranges in size from 4" to 10”, with 7" being the most popular size.

What Is a Cleaver Used For?

- Chopping vegetables

- Slicing and tenderizing meat

- Crushing garlic

4. Paring Knife

Paring knives are lightweight and have a short blade with a pointed tip that makes them useful for delicate knifework. Their blade lengths range between 2 1/4” and 4 1/2” and can feature a serrated or straight edge to handle a wide variety of tasks. The most common styles of paring knives are the spear point, bird's beak, and sheep's foot, which are named after the shape of the blade's tip.

What Is a Paring Knife Used For?

- Cut, chop, and slice fruits, vegetables, and some cheeses

- Peeling skins for garnishes

- Deveining shrimp

- Trimming excess fat off meat

5. Butcher Knife

Butcher knives have a long, curved blade with a sharp point at the end, which helps with cutting through meat cleanly and easily with a sawing motion. They feature a granton or straight edge to easily slice through meat without tearing or shredding the product. A butcher knife's blade length ranges in size from 5" to 12”, with 8" to 10" being the most popular size range.

What Is a Butcher Knife Used For?

- Cutting through skin, cartilage, and bones

- Portioning large portions of meat, including whole carcasses, racks of ribs, and beef primal cuts

- Trimming fat and sinew

6. Bread Knife

Bread knives have a long, straight blade with a serrated edge that is perfect for sawing through soft items while keeping them intact. Some bread knives feature offset handles, which are designed to prevent the user’s knuckles from hitting the cutting board. A bread knife's blade length ranges in size from 5" to 14”, with 8" to 10" being the most popular size range.

What Is a Bread Knife Used For?

- Cutting through bread and some cakes without crushing them

- Slice tomatoes without bruising or tearing them

- Slicing through cooked meat and sandwiches

7. Boning Knife

Boning knives can have either a narrow or wide blade that comes in flexible, semi-flexible, or stiff options, depending on the type of meat you are cutting and how maneuverable you need the knife to be. For example, narrow, flexible blades are great for cutting and shaping lamb, veal, and fish whereas a wide, stiff blade is ideal for deboning beef and pork. A boning knife's blade length ranges in size from 3" to 12”, with 6" being the most popular size.

What Is a Boning Knife Used For?

- Separating meat from bones while reducing the amount of wasted meat

- Cutting through cartilage

- Precisely trimming fat

- Filleting fish

8. Oyster Knife

Oyster knives are an essential tool for any restaurant that shucks its oysters. There are several types of oyster knives that are used for opening different sizes of oysters but they all commonly share a pointed tip that is perfect for unhinging the oyster's shell. Boston-style oyster knives are the most common oyster knife shape and have long, narrow blades that are effective at opening oyster shells regardless of their size. This makes Boston-style the perfect oyster knife for shucking beginners. Most oyster knives feature an hourglass-shaped handle to ensure a comfortable, secure grip.

What Is an Oyster Knife Used For?

- Opening oyster shells

- Removing the meat from the shell

9. Carving Knife

Carving knives, or slicing knives, have a long, narrow blade that tapers to a sharp point. They are much thinner than chef knives, enabling them to carve thin, uniform slices from cooked poultry and large roasts. This makes carving knives the best knife for carving stations at catered events. Many slicing knives feature granton edges, which reduces drag and prevents the meat from tearing while cutting. A carving knife's blade length ranges in size from 8" to 14”, with 10" being the most popular size.

What Is a Carving Knife Used For?

- Slicing uniform cuts of cooked turkey, ham, chicken, and beef roasts

- Cutting cakes

10. Cheese Knife

Cheese knives are smaller knives that are typically served with cheese for slicing and portioning. There are several types of cheese knives with different blade styles and lengths that are specially designed to cut through soft, semi-soft, and hard cheeses. Some cheese knives are designed with holes that prevent the cheeses from sticking to them for ease of use. Cheese knives are the perfect tool for restaurants and caterers that offer grazing and charcuterie boards on their menus to enhance the user experience.

What Is a Cheese Knife Used For?

- Slicing cheese on a charcuterie board

- Spreading soft cheeses on crackers

11. Santoku Knife

Santoku knives are a type of Japanese knife that features a wide, straight blade and a curved spine that rounds to the point. Compared to a chef knife, a santoku knife has a thinner, more lightweight blade that is better suited for precise, thin cutting and fine chopping. In most cases, they can be used as an alternative to chef knives in the kitchen because of their all-purpose design. A santoku knife's blade length ranges in size from 5" to 9”, with 7" being the most popular size.

What Is a Santoku Knife Used For?

- Slicing and dicing fruits, vegetables, meats, and fish

- Mincing garlic, meat, or herbs

- Chopping nuts

12. Nakiri Knife

Nakiri knives are Japanese-style knives with a thin, lightweight, rectangular blade and a razor-sharp straight edge. Nakiri knives are slightly heavier than santoku knives since they are designed for straight up and down chopping for precise, clean cuts. It makes quick work of cutting through onions, ginger, and other vegetables. A nakiri knife's blade length ranges in size from 5" to 9”, with 7" being the most popular size.

What Is a Nakiri Knife Used For?

- Slicing, dicing, chopping, julienning, and ribboning vegetables

- Chopping herbs

- Mincing garlic

13. Tourne Knife

A tourne knife, or a bird's beak paring knife, has a short 2 1/4" to 3" blade that curves downward, mimicking the shape of a bird’s beak. This allows you to closely grip the knife to peel small and odd-shaped food, such as a knob of ginger, with ease. The tourne knife is the primary knife used to make tournee cuts, a French technique that involves turning and cutting vegetables into a seven-sided oblong, football shape to promote even cooking.

What Is a Tourne Knife Used For?

- Cutting potatoes, zucchini, carrots, apples, and pears

- Peeling onions, shallots, and round fruits

- Coring tomatoes, strawberries, and brussel sprouts

- Creating garnishes for cocktails

14. Breaking Knife

Breaking knives are a type of butcher knife that is used for cutting large sections of meat into smaller, more accessible cuts. A breaking knife's blade is more narrow, thin, and curved than a traditional butcher knife, which gives the user additional leverage and flexibility when cutting through tough skin, cartilage, and small bones. A breaking knife's blade length ranges in size from 7" to 10”, with 8" being the most popular size.

What Is a Breaking Knife Used For?

- Break down whole animal carcasses and larger sections of meat

- Cut through tough skin, cartilage, and small bones

- Trimming the fat off cuts of meat

15. Cimeter Knife

Cimeter knives, or scimitar knives, are a type of butcher knife that is very similar to a breaking knife. Cimeter knives have a long, sharp, curved blade with either a granton or straight edge and are more lightweight than a breaking knife. When used for butchering whole animals, cimeter knives are typically used after a breaking knife as the final portioning knife to trim meat away from the bone to make steak and other retail cuts. A cimeter knife's blade length ranges in size from 10" to 14”, with 10" being the most popular size.

What Is a Cimeter Knife Used For?

- Trim meat and fat off of bones

- Break down sub-primal cuts into retail cuts

Table knives are essential pieces of flatware to have for your dining service. Let's go over the 5 types of table knives and when to use them in your establishment.

1. Butter Knife

Butter knives have a short, broad shape and a dull, rounded edge, which allows the user to spread butter without scoring the bread. In comparison to a dinner knife, a butter knife has a duller edge and is exclusively used for slicing and spreading pats of butter so that diners don't have to dirty their dinner knife or steak knife before the main course arrives.

- Ideal for spreading butter, jam, cream cheese, and other spreads

- Serve with rolls, crusty bread, scones, and english muffins

- Typically used in fine dining establishments, tea houses, and on charcuterie boards

2. Steak Knife

Steak knives have a similar blade length to a dinner knife but have a serrated edge and a pointed tip. This design helps to pierce through a meat's crust without damaging its delicate interior and is best for cutting tough meats that are too thick to cut with a dinner knife.

- Perfect for cutting through tough cooked meat like steak and pork chops

- Must-have for steakhouses, fine dining restaurants, and other establishments serving a lot of meat dishes

- Come in a variety of handle types

3. Fish Knife

The fish knife was invented in the Victorian era around 1850 when fine dining often included a soup course, fish course, and meat course, and each course had specialized flatware. Fish knives have a short, curved, paddle-like blade that is ideal for sliding between the fish’s skin and flesh. The blade's pointed end allows diners to remove the tiny bones from delicate pieces of fish, which is especially helpful when eating a whole fish.

- Ideal for serving with fish fillets and whole fish

- Typically only used in fine dining establishments

4. Dinner Knife

Dinner knives are the standard knife to use for breakfast, lunch, and dinner. They feature a long, slightly curved blade and a small serrated edge that allows them to cut through a variety of cooked foods. They are typically made of stainless steel but can come in different finishes, such as silver, gold, or black to customize your tablescape.

- Use to cut everything from meat and vegetables to fish and salad greens

- Come in a variety of finishes and handle styles

5. Dessert Knife

A dessert knife resembles a dinner knife but is slightly smaller in overall length. They are great for serving with dessert as a fresh alternative to dinnerware that has been dirtied while eating an entree. They have a slightly serrated edge that is useful for cutting through soft items like cakes, cheesecakes, and pastries.

- Perfect for serving pies, cakes, or pastries

- Ideal for upscale restaurants, hotels, and catered events

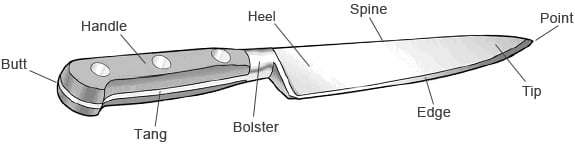

Understanding the parts of a knife is integral to learning about the various types of kitchen knives and how they're different. The graphic below shows the parts of a knife to help you identify them on your kitchen knives.

Here's an explanation of the different parts of a knife:

Bolster: The bolster is only found on forged knives. It is a thick band of steel between the heel and the handle that helps balance the weight of the knife and prevents the user's hand from slipping.

Butt: The butt is the end of the knife's handle.

Edge: The edge is the sharpened side of the knife's blade that you use to cut. Keeping your knife's edge sharp prevents accidents while cutting.

Handle: The handle is the section where the user holds the knife. This part of the knife may also be referred to as the scales.

Heel: The heel is the rear portion of the blade, and it's most often used for cutting tasks that require a lot of force, such as cutting meat or dense vegetables.

Point: The point is the tip of the knife. It is often used for piercing through products.

Spine: This is the unsharpened side of the knife blade that is opposite the edge.

Tang: The tang is the part of the blade that extends into the handle to provide balance. Full tang blades are considered superior in balance and durability. A sub tang or half tang knife is less durable but more economical.

Tip: The tip is the front quarter of the blade that does most of the cutting and separating. Point tips are ideal for piercing and cutting small portions whereas rounded tips are ideal for cutting or slicing thin portions.

Carbon steel and stainless steel are the two most common types of steel used to make kitchen knives. Let's go over the benefits and drawbacks of each material so you can decide which is best suited for your tasks.

Carbon Steel

Carbon steel is a type of steel alloy that contains a higher percentage of carbon than stainless steel but a lower percentage of chromium. The higher carbon content results in a harder blade than stainless steel types, but it is more susceptible to rust. It is the preferred steel type for professional chefs because of its wear resistance, and most Japanese steel blades are made with high-carbon steel.

- Provide exceptional strength and rigidity

- Can be honed to a very sharp edge

- Hold their edge for a long time under frequent use

- Easier to sharpen

- Susceptible to rust and staining

- More brittle than stainless steel knives

- Can chip and break under extreme pressure

Stainless Steel

Stainless steel is a type of steel alloy that contains a higher percentage of chromium than carbon steel, which gives stainless steel blades their corrosion resistance. The trade-off is that stainless steel blades are not as hard as carbon steel blades and are more difficult to maintain a sharp edge. VG-10 steel is a popular type of stainless steel that is commonly used to make professional-grade cutlery.

- Easy to maintain

- Resists stains and corrosion

- Not as brittle as carbon steel

- Not as hard and wear-resistant as a carbon steel blade

- More difficult to re-sharpen

Every kitchen knife is constructed using one of two methods: forging or stamping. Forged knives are made when a bar of steel is heated and hammered to form its shape. The blade then goes through a grinding and honing process to form its final shape and edge. The forging process adds strength to the steel and makes the blade less flexible, which keeps the edge sharper for longer.

Stamped knives are formed when a hydraulic press or die cuts the blade shape out of a sheet of steel. This process creates the basic shape of the blade, called a blade blank, which is then ground and honed to give it an edge. Stamped knives are thinner, more lightweight, and more flexible than forged knives.

Forged Knives

Forged knives are heavier, thicker, and less flexible than stamped knives to deliver more power behind each cut. They are ideal for heavy-duty chopping, mincing, slicing, and dicing tasks and are a more reliable choice for cutting through hard surfaces. One way to easily distinguish a forged knife from a stamped knife is the presence of a bolster. The bolster provides a safe place to rest your fingers while cutting for enhanced safety and balances the knife to provide the user with a more stable grip for precise control.

- Stronger than stamped knives

- Have a bolster between the handle and the heel

- Have a full tang for better balance

- Won't warp or bend when cutting through hard surfaces

- Easier to manually sharpen

- More expensive

- Heavier weight can lead to user fatigue more quickly

Stamped Knives

Stamped knives are more lightweight and flexible than forged knives. This makes them great for long periods of prepping or repetitive tasks where you want to minimize user fatigue as well as for boning, filleting, or making sushi where blade flexibility is beneficial. However, their flexibility makes them harder to control when cutting and sharpening manually. Stamped knives are less expensive than forged blades, making them a great option for when you need a large assortment of knives for your kitchen. While stamped knives do not have bolsters, many come with finger guards to enhance user safety.

- The lighter weight makes them more comfortable to use for extended periods

- Flexibility is great for light chopping, boning, filleting, and other delicate knifework tasks

- More affordable than forged knives

- Many come with finger guards to enhance user safety

- Edge typically needs to be sharpened more often

- Harder to manually sharpen

- May bend and warp when cutting through hard surfaces

- Lack of bolster makes them less balanced than forged knives

There are three main types of knife edges: granton edge, straight (or smooth) edge, and serrated edge. The type of knife edge you will want on your kitchen knife will largely depend on the food you are cutting.

Granton Edge

- Creates air pockets between the blade and food for more fluid slicing

- Prevents wet and sticky foods from sticking to the blade after each cut

Straight Edge

- Makes smooth, clean cuts with a few simple strokes

- Best for hard and soft fruits, vegetables, and meats

Serrated Edge

- Saw through items with a hard exterior and soft interior while keeping them intact

- Best for bread, cakes, and produce with skin

There are three main types of knife handle styles: plastic, stainless steel, and wooden. The most important aspect to look for in a good knife handle is a comfortable, stable grip. Plastic and wood handles are the most common handle types among kitchen knives whereas stainless steel handles are more common for table knives. While wood is the most traditional handle material used for kitchen knives and provides unparalleled balance, durability, and aesthetic, they do require more care and maintenance, which may not make them the most practical choice for your commercial environment.

Plastic Handle

- Durable, lightweight, easy to clean, and economical

- Provide a comfortable, stable grip

- Come in many types like nylon, resin, and POM

Wood Handle

- Attractive and comfortable to use

- Naturally non-slip

- Harder to clean and can trap bacteria

Stainless Steel Handle

- Very durable and easy to clean

- Provide balance and weight for table knives

- Can become slippery when wet

Plastic knife handles come in a variety of colors, allowing you to designate your knives for certain foods to prevent cross-contamination and practice good food safety habits.

Proper sharpening, cleaning, and storage are all important knife safety tips to keep in mind when caring for your cutlery and ensuring safety in the workplace. Below are a few tips to keep in mind to maintain your knives.

- Clean your knife as soon as you are done using it to prevent cross-contamination

- Wash your knives by hand rather than running them through the dishwasher

- Regularly sharpen and hone your knives to keep the blade sharp

- Allow knives to air dry completely before storing them

- Store knives in a designated knife storage space

Storing your knives improperly can lead to accidental injuries and impact their longevity and sharpness. Below are a few ways you can store knives to ensure your kitchen is organized and safe.

Knife Blocks/Racks: These include slots to fit a variety of knife types in the same location. Choose from wall-mounted or countertop knife blocks and racks based on your kitchen needs. Be sure to check the compatibility of the holder with your knives before purchasing.

Magnetic Knife Holder: Featuring strong, hidden magnets, magnetic knife holders can be flush-mounted above a sink or near a food-prep area for quick knife access. They can hold any metallic kitchen utensil, allowing you to keep your kitchen sheers, peeler, and any other frequently-used tool near your knives for convenience.

Knife Bags: A durable knife roll will help you organize, store, and transport your kitchen cutlery safely and easily. They are useful for culinary students, private chefs, and trade shows.

Related Resources

February 2026 WebstaurantStore Coupon Code

Love is in the air, and so are great deals all February long here at Webstaurantstore! Whether you're looking to get ahead of planning for St. Patrick's Day or shopping for supplies and ingredients for the upcoming Lunar New Year, we've got deals for you! Check out our selection of sale items below and don't forget to enter the code LOVE26 at checkout to enjoy up to 20% off your purchases! Shop All February Coupon Items Looking to save even more? Check out the new Webstaurant Rewards® Visa Business Card ! Sign up for a new card today and start earning rewards on every WebstaurantStore purchase, and save on a WebstaurantPlus subscription. Fall in love with incredible deals on winter disposable items with February's monthly coupon code! Wheth

Types of Knife Cuts

Restaurant kitchens write their recipe cards with the knife cut sizes in mind, so you must learn how to perform the classic culinary knife cuts to become a chef . Skillful knife cuts aren't just about presentation; they ensure food cooks evenly, enhance texture, and release aroma. Whether you're considering attending culinary school or want to move up the kitchen hierarchy , use our types of knife cuts guide to brush up on the basics. Click any of the links below to skip to the type of knife cut that most interests you: Dice Julienne Mince Chiffonade Chop Brunoise Rondelle Batonnet Paysanne Knife Cutting Techniques Different Knife Cuts Discover the essential knife cuts used in the culinary arts. From functional to decorative, each of these

Best Chef Knives

Chef knives are the cornerstone of a professional kitchen, used for anything ranging from mincing garlic to butchering meat . However, choosing the best chef knife for your toolkit is daunting, especially with the vast array of materials, styles, and sizes. While the perfect pairing between chef and knife boils down to personal preference, we narrowed the field by selecting our choices for the best chef knives on the market for commercial kitchens. Shop All Chef Knives