Choosing the Best Kegerator

What is a Kegerator?

A kegerator makes it easy to keep ice cold beer on tap, providing an efficient way to serve your guests. Kegerators come in different designs with various features to meet any specific business's needs. Kegerators are also designed to hold various amounts of kegs, as well as various keg sizes, ensuring your restaurant or bar's volume needs are met.

How Does a Kegerator Work?

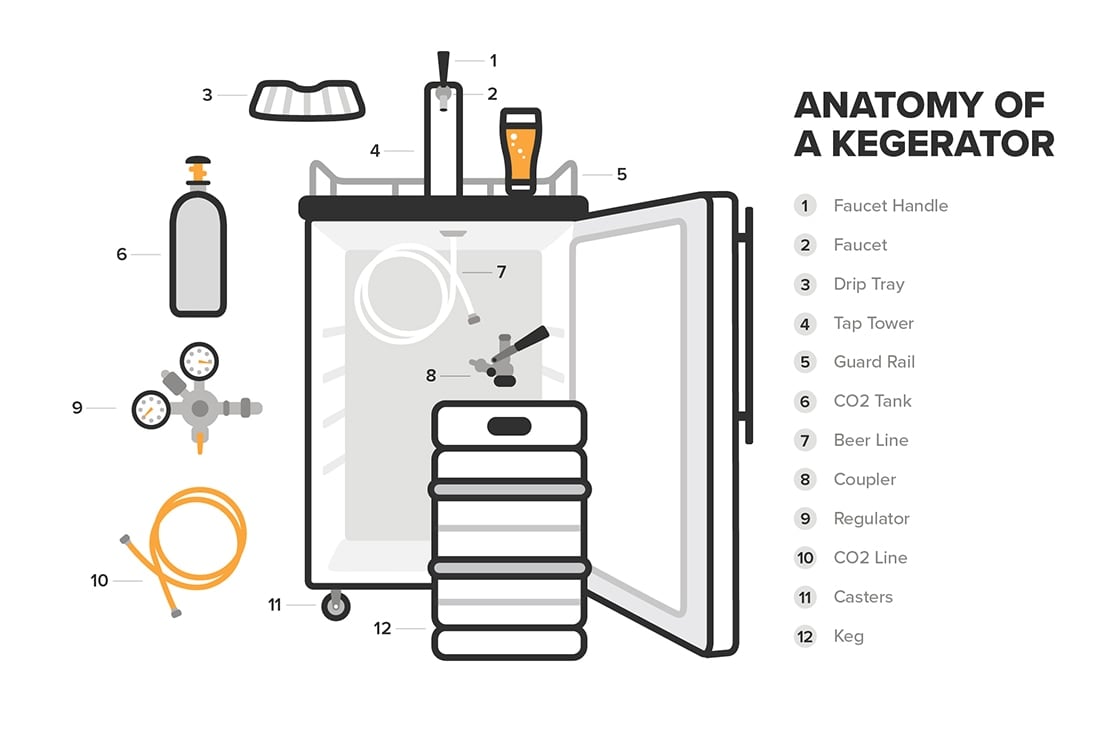

On a basic level, kegerators have a hollow inner cavity where the keg is stored, a standard latching or sealing door, and a dispensing tower, which is located on the top of the unit. However, there's a lot more that goes into them. Taking the time to learn how to use a kegerator is an important part of taking proper care of your unit.

- Faucet Handle: Faucet handles are available as direct replacements or unique upgrades that boost the visual appeal of your tower. Some even include writable surfaces which are great for ever-changing beer menus.

- Faucet: Faucets are attached to the tap towers and they dispense the beer. The number of tap towers is not always the same as the number of faucets, as multiple faucets can be attached to each tower.

- Drip Tray: The drip tray sits on top of the unit at the base of the tap tower. It conveniently collects beer overflow or accidental spills when dispensing.

- Tap Tower: Beer travels from the keg to the tap tower where it is almost ready to be dispensed. Tap towers come in many different styles with varying numbers of faucets.

- Guard Rail: Guard rails rest on top of the kegerator. If you choose to store glasses on top of the unit, this rail will keep them from falling off.

- CO2 Tank: Carbon dioxide enters the keg through the coupler, which allows the gas to push beer up through the beer line and into the tap tower.

- Beer Line: The beer line attaches to your coupler, carrying the beer from your keg up through the tower and eventually out the faucet.

- Coupler: The coupler is a valve that taps the keg.

- Regulator: The regulator is connected to the CO2 tank, and it allows you to change the pressure or maintain a constant one.

- CO2 Line: This line connects from the regulator to the coupler, working in conjunction with the CO2 tank to push beer through the beer line.

- Casters: Casters allow for easy maneuverability on freestanding units.

- Keg: The keg is where beer is both stored and chilled in the kegerator.

Note: Unless stated otherwise, most kegerators do not include these parts. You will need to buy the essentials, like the CO2 tank, tap tower, coupler, and regulator separately.

How Long Does a Keg Last in a Kegerator?

To ensure your beer is being stored at the proper temperature, most craft breweries follow these temperature recommendations:

- Macro-brand beers (pale lagers, light beer): 34 to 38 degrees Fahrenheit

- Craft beers such as pale lagers, light ales: 41 degrees Fahrenheit

- Craft beers such as standard ales, amber lager, dark lager, ciders: 46 degrees Fahrenheit

- Craft beers such as high-alcohol or malty styles including imperial stout, old ale, barleywine: 50 to 55 degrees Fahrenheit

Kegerator Types & Dimensions

Indoor kegerators are great for bars, pubs, and caterers who are doing indoor events. They fall under the indoor kegerator category because they should not be used in environments below 50 degrees or above 85 degrees. Take this into consideration when deciding on the kegerator that is right for you. Some units are freestanding and others have the option of being built into a countertop. Before you start your search, it's important to note that all indoor kegerators fit into three main categories: single keg units, multiple keg units, and multi-purpose units. Next, we'll outline the various features of each type.

Single Keg Units

These are the smallest kegerators available and, as a result, they hold the least amount of beer. Still, you might be surprised at just how many people one of these can serve. A single 1/2 barrel keg holds about 15 1/2 gal. of beer, or approximately (165) 12 oz. servings. The average customer will have 1.5 drinks per night, meaning that a single keg will serve draft beer to approximately 110 people. The convenient size of single keg units makes them great for caterers looking for something that is both easily maneuverable and durably built. Due to the lower capacity of these single keg units, many are freestanding and cannot be built into a countertop. Depending on the model, you may also need to store the CO2 tank outside the unit because of space restrictions.

Multiple Keg Units

Multiple keg units offer more keg configurations for added flexibility and more beer! Most likely, if you're looking for something with a larger capacity, you want to install it directly into your bar rather than use it as a freestanding unit. Casters can be purchased, though, if you want the option to move the machine around more easily. Multiple keg models include extra tap towers for increased serving efficiency. The extra towers, often attached to their own kegs, allow you to serve more than one kind of draft beer. Multiple keg units can typically hold (2-5) 1/2 barrel kegs depending on the model you choose.

- 2 kegs hold (330) 12 oz. servings; serves about 220 people

- 3 kegs hold (495) 12 oz. servings; serves about 330 people

- 4 kegs hold (660) 12 oz. servings; serves about 440 people

- 5 kegs hold (825) 12 oz. servings; serves about 550 people

Multiple keg units can also accommodate sizes of kegs other than the traditional 1/2 barrel, such as a 1/4 barrel or the less common 1/6 barrel for more keg configurations. These smaller kegs are ideal for sampling, but they're not great for serving a big crowd.

Multi-purpose Units

Multi-purpose units give you maximum versatility. These machines include club top units that boast room to store bottles and cans in addition to your keg(s) through a top door. The club top units provide convenient access to speed up the serving process for your bartenders or waitstaff. Club tops generally store six packs or smaller amounts of beer, soda, or other canned beverages of your choice. They can also be used to frost glasses so your customers can indulge in an ice cold beverage.

How to Set Up a Kegerator

Setting up a kegerator is a fairly simple process, but requires a few steps:

1. To begin, if your kegerator included casters, install the casters to the bottom of the unit. Flip the unit over so that it rests on the casters.

2. Attach the tap tower to the kegerator by removing the plug covering the hole with a screwdriver. Feed the tubes in the tap tower through the hole, and pull them into the inside of the kegerator. Use screws to secure the tap tower onto the kegerator, lining up the holes in the tower with the holes on the kegerator.

3. Attach the railing to the kegerator. It should snap into place when aligned with the holes on the top of the cabinet.

4. Install the faucet by screwing it on to the faucet adapter at the front of the tap tower. Screw the black handle onto the faucet.

5. Attach the beer line to the kegerator coupler. Place a rubber washer into the beer line hex nut, and connect the line to the top of the coupler, using a hex nut wrench to secure the line.

6. Make sure the CO2 regulator shut off valve is closed, and then connect the CO2 gas line tube to the regulator. Push the tube firmly into the regulator, using a screw clamp or pliers to ensure it is pushed into place. Connect the opposite end of the gas line tube to the house barb, on the side of the coupler. Again, push the tube firmly to ensure it is pushed into place.

7. Attach the CO2 regulator to the cylinder, making sure the cylinder is closed. Screw the inlet nut into the cylinder valve, and tighten it with a wrench.

8. Attach the coupler to the keg, ensuring the coupler is in the closed position, then screwing the coupler into the locking neck on the keg.

9. Carefully place the CO2 holder into the cabinet mounting it to the holder on the inside or outside of the kegerator. Make sure the regulator is still visible. Open the air tank by turning the wheel on the tank, and moving the shut off valve on the regulator to the "on" position.

10. Calibrate the regulator, and set it to the PSI level. Adjusting the PSI can be done by turning the pressure adjustment with a screwdriver. Adjust the pressure slowly, setting it to your desired PSI; this should be between 10-15 PSI. Then, set the temperature to be between 36-40 degrees Fahrenheit.

11. Carefully place the keg in the bottom of the cabinet, and close the kegerator door. At this point, you will be ready to dispense beer!

How to Assemble a Kegerator

0:00

Light Duty Kegerators

This Galaxy single keg unit is great for caterers and first time kegerator buyers looking to serve draft beer at parties and other small scale events. Guests will love being served draft beer, and you'll actually save money in the long run by cutting costs on bottles. One of the biggest advantages to this model, in particular, is that it comes with almost everything you need to get started right out of the box, including an empty CO2 tank, a dual regulator, a tap, and 3" casters that allow for easy maneuverability. Just have the CO2 tank filled, plug the machine into the wall, and you're ready to start drinking and serving draft beer! It has a temperature range of 32-50 degrees Fahrenheit and comes in either a black or stainless steel finish with a plastic liner interior. This kegerator is UL Listed.

Kegerator Taps

A kegerator tap, also known as the coupler, is what you use to dispense beer from the keg. Tap towers are designed to accompany the faucet, and hold the tubing that pushes beer through the line. Its important to choose the correct coupler and tap tower for your kegerator, as they are available in a variety of sizes and styles. Couplers are also often the dirtiest part of a kegerator, and should be thoroughly cleaned on a regular basis.

Most kegs use the American Sankey "D" system keg coupler. It is important to remember that most of the units we carry do not include a coupler. For more information about couplers and other specific kegerator parts, check out our Draft Beer Tap Towers, Faucets, and Components Guide.

How to Clean a Kegerator

Knowing how to clean kegerator lines is crucial in ensuring your beer looks and tastes as fresh as possible. This should be done at least once every 2-3 weeks, and even more often for high-volume establishments. Make sure you use the proper chemicals to ensure the kegerator is clean, and purchase a cleaning kit to make the process as easy as possible.

- To begin, remove the faucet, coupler, and any washers from the tap tower. Let these items soak in a bowl of warm water mixed with cleaner, and then use a brush to clean the parts.

- Wipe down the outside of the kegerator, cleaning up any residue or puddles of beer.

- Prepare the beer line cleaner according to the package instructions. Pour this cleaner into the bottle included with the cleaning kit.

- Put the beer hose in a bucket, and connect the cleaning bottle attachment to the faucet head (where the faucet was previously removed). Then, pump the cleaning solution through the lines. You should flush the lines at least two times.

- After this, fill the bottle with hot water, and pump this through the lines at least two more times.

- Reassemble your kegerator by putting the washers, coupler, and faucet back on the tap tower. Make sure everything is secure and in place, then tap the keg. Your kegerator will be clean and ready to dispense fresh beer!

Related Resources

Beer Glass Buying Guide

Whether you own a taphouse or brewery , using the right glassware to serve your beers will highlight the characteristics that make each style unique. Color, carbonation, and aromatics can all be enhanced by the shape and thickness of the glass. Using the appropriate glassware for each type of beer has the potential to improve the craft beer experience for your guests. Keep reading to learn all about the beer glass types available and which beers they complement the most. Shop All Beer Glasses Click below to learn more about each type of beer glass: American Pint Glass Imperial Pint Glass Pilsner Glass Weizen Glass Snifter Glass Tulip Glass Beer Goblet IPA Glass Stout Glass Stange Glass Dimple Beer Mug Beer Boot Types of Beer Glasses Chart

Beer Dispenser Installation and Maintenance

Designed to quench the thirst of dozens of customers, beer dispensers are excellent additions to restaurants, bars, catered events, and more. Their simple design makes them easy to use, and they have the capacity to serve dozens before needing a refill. Just like any other type of equipment, these systems require routine maintenance . In this guide, learn how to select the right dispenser for you, how to set it up, and find recommendations for upkeep and cleaning. Shop All

Maintaining a Commercial Beer Tap System

Part of running a successful bar business is knowing how to identify and resolve common draft system problems when they inevitably arise. This guide will go over how to troubleshoot various beer tap problems so you can train your bartenders to calmly and quickly handle the issues as soon as they happen. Use these links to jump to the beer tap problem you need to troubleshoot: Keg Is Not Pouring Beer Is Foamy Beer Is Flat Beer Won't Hold a Head Beer Is Cloudy Beer Tastes Bad Keg Is Not Pouring If the keg is not dispensing beer or the beer is coming out of the tap too slowly, here are some easy troubleshooting tips to ensure you get your beer flowing again quickly: Your keg is empty. Replace the empty one with a fresh keg. You can also use a

- Topics 1356

- Industrial 55

- Troubleshooting Guides 21

- Restaurant Management 128

- Bar Management 56

- Catering Tips 36

- Bakery Management 42

- Food Trucks & Concessions 49

- Advertising & Marketing 37

- Eco-Friendly Tips 11

- Facility Layout & Design 42

- Coffee Shop Tips 28

- Installation & Maintenance 51

- Janitorial & Pest Control 30

- Safety & Sanitation 88

- Startup Tips 104

- Menu Design 10

- Kitchen & Cooking Tips 83

- Hospitality Management 24

- Pizza & Sandwich Shop Tips 36

- Smallwares 37

- Food Prep 89

- Tabletop Items 17

- Disposables 22

- Calculators & Tools 6

- Consumables 52

- Warewashing & Laundry 19

- Cooking Equipment 91

- Food Storage & Refrigeration 51

- Beverage Equipment 35

- Office Supplies 6

- Resource Type

- In-Depth Articles272

- Buying Guides298

- How-Tos95

- Product Reviews78