Types of Work Gloves

Ensuring hand safety at work begins by selecting the appropriate glove. Various materials and coatings offer different levels of protection against injuries, so it's important to carefully assess the specific protection you need from your work glove. We'll go over common types of work gloves so you can choose the best glove for the task at hand.

Shop All Safety Gloves

Types of Work Gloves

Work gloves are an essential form of personal protective equipment (PPE) across various industries. They protect workers' hands while performing tasks that may pose risks of cuts, abrasions, burns, or other injuries. Work gloves come in a range of materials, offering different levels of protection for light-duty and heavy-duty tasks. Selecting the right type of work gloves is crucial to ensure safety and efficiency in the workplace.

Leather Work Gloves

Leather work gloves are a popular choice for their durability and protection. Made from animal hide, leather work gloves are typically crafted using pigskin, cowskin, or goatskin. Among these options, cowhide leather gloves are the most common and economical choice for various industries.

Known for their excellent abrasion, cut, and puncture resistance, leather gloves are ideal for heavy-duty tasks. Their long-lasting durability ensures they can withstand tough conditions, making them suitable for construction work, woodworking, and masonry. For those in the welding industry, leather welding gloves are a heavy-duty option that offers high heat resistance. These gloves are designed to protect against extreme temperatures and provide additional safety for welders working with hot materials.

Jersey Work Gloves

Jersey work gloves are a popular choice for various industries due to their versatility and affordability. These gloves are typically made from 100% cotton or a blend of cotton with other fabrics like polyester or nylon. The combination of materials makes them light weight and breathable, allowing for extended use without causing discomfort or overheating.

These gloves are ideal for tasks that require manual dexterity, such as landscaping, warehouse operations, assembly work, and other light-duty jobs that involve handling materials or tools. The soft and flexible nature of cotton/fabric gloves enables users to maintain a good grip and perform intricate tasks with ease. One of the key advantages of cotton/fabric work gloves is their cost-effectiveness. They offer reliable hand protection at a budget-friendly price point, making them a practical choice for businesses looking to provide quality safety gear without breaking the bank.

Cut-Resistant Gloves

Cut-resistant work gloves are essential for industries where workers are at risk of cuts and lacerations from sharp materials, cutting tools, or machinery. These gloves provide a protective barrier to safeguard workers' hands from potential injuries, ensuring a safe work environment. Crafted from a variety of durable materials, cut-resistant gloves are designed to withstand the demands of tough working conditions.

Despite their sturdy construction, these gloves are typically light weight, allowing for comfortable wear during extended periods of use. They offer a high level of dexterity, allowing workers to maintain precision and flexibility in their movements.

Chemical Protection Work Gloves

Chemical protection gloves are designed to repel and resist the penetration of liquids, fluids, and chemicals. These gloves are commonly made with materials such as nitrile, PVC, neoprene, or latex, which offer excellent resistance to various chemicals and solvents. They feature a longer safety cuff for added protection to the wrists and arms.

Chemical protection gloves are ideal for a range of industries and applications, including mechanics, construction sites, manufacturing plants, and medical facilities. When selecting your gloves, consider the specific types of chemicals or substances that will be encountered to ensure the gloves provide the necessary level of protection.

Cold Protection Work Gloves

When working in cold weather conditions or freezers, having the right type of work gloves is essential to protect your hands and maintain productivity. Cold protection work gloves are designed to provide warmth and dexterity in low-temperature environments.

These gloves feature an outer layer with a sturdy grip, allowing you to handle tools and equipment even in cold conditions. The insulated inner layer helps to retain heat, keeping your hands warm throughout your workday. Additionally, a layer to wick away moisture helps to keep your hands dry and comfortable, reducing the risk of frostbite or discomfort. Look for gloves where the insulation wraps around each finger, not just the front and back.

Disposable Gloves

Disposable gloves are a crucial part of maintaining hygiene and safety in various industries, especially in the food and health sectors. Commonly made with nitrile, these gloves are widely used in the food and health industry to prevent cross-contamination and the spread of germs and bacteria.

They are ideal for workers who need to change gloves frequently. Whether handling food, performing medical procedures, or working in a laboratory setting, these gloves offer a quick and easy solution for maintaining cleanliness. Additionally, disposable gloves are comfortable to wear and provide a high level of dexterity, making them a practical choice for various tasks.

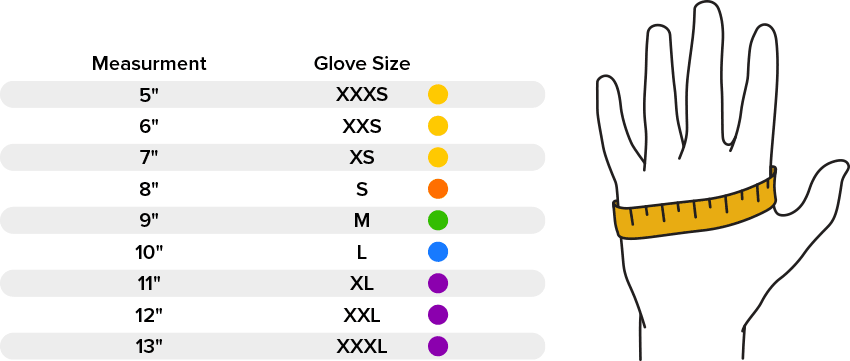

How to Measure Glove Size

Before buying your work gloves, measure your glove size to ensure proper usage and safety. To determine the correct glove size for you and your employees, measure the circumference of your hands, just under your knuckles.

The chart below is an approximation, so to verify that your glove size is correct for any gloves that you purchase, be sure to check the manufacturer's sizing.

Parts of a Work Glove

Below are the four main parts of a work glove that provide protection to the hands and wrists:

1. Palm Coating: The palm coating of a work glove plays a crucial role in providing grip, protection, and durability.

2. Shell Material: The shell material of a work glove determines its overall durability, comfort, and protection level. Common shell materials include cotton, nylon, leather, and polyester.

3. Cuff: The cuff of a work glove secures the glove on the hand and prevents debris from entering. There are different cuff styles available, including knit wrists, safety cuffs, and gauntlet cuffs.

4. Thermo-Plastic Rubber (TPR): TPR is an additional form of protection that you may find in certain gloves to offer further cushioning during tough jobs. It is a light weight and flexible material that can absorb and disperse impact energy, reducing the risk of hand injuries. Work gloves with TPR reinforcements on the knuckles, fingers, and back of the glove offer enhanced protection in high-impact environments. TPR enhances grip and dexterity, allowing users to maintain control while handling tools and equipment.

Work Glove Palm Coating

There are various types of palm coatings that you may find on a glove, each providing a different type of additional protection for the user. These coatings serve as additional layers to ensure safety while maintaining the flexibility traditionally found in the glove shell's material.

- Canvas: Work gloves with a canvas palm coating are light weight and breathable. They are durable and provide some protection but are best suited for general-purpose tasks.

- Latex: A latex palm coating provides an excellent grip in dry conditions and is resistant to liquids and chemicals.

- Leather: A leather palm coating offers superior durability and abrasion resistance, and it is often found on work gloves suitable for heavy-duty tasks such as construction, welding, and landscaping. The leather coating can come in pigskin, which provides maximum breathability and remains soft and pliant when wet, cowhide, which offers protection against abrasions while remaining flexible, or goat skin, which provides tactile sensitivity while remaining soft and pliable.

- Nitrile: Nitrile-coated work gloves protect against abrasions, snags, punctures, and cuts while resisting oils and solvents. They are popular for industrial applications that handle sharp objects or hazardous materials.

- Polyurethane: Polyurethane-coated work gloves provide a good grip and tactile sensitivity, making them ideal for precision work such as assembly, electronics, and inspection tasks. They also resist oils, solvents, gasoline, and oxidation.

- PVC: PVC-coated work gloves provide excellent flexibility and a firm grip in wet or oily applications. They offer excellent resistance to abrasions, chemicals, and oils, making them suitable for tasks that require protection against harsh environments.

Work Glove Material Applications Chart

We've listed what glove materials are best for certain tasks like landscaping or construction, making it easier than ever to help you decide the best work glove for your needs.

material | Construction / Warehouses | Inspector | Mechanic | Driver | Landscaping / Garden Work | Painting | Handling Chemicals | Electrical Work |

|---|---|---|---|---|---|---|---|---|

Aramid/Cotton | ||||||||

Blended | ||||||||

Canvas | ||||||||

Cotton | ||||||||

Engineered Fiber | ||||||||

Glass Fiber | ||||||||

HPPE | ||||||||

Kevlar® | ||||||||

Latex | ||||||||

Neoprene | ||||||||

Nitrile | ||||||||

Nylon | ||||||||

Polyester | ||||||||

PVC | ||||||||

Spandex | ||||||||

Spectra | ||||||||

Synthetic Fiber | ||||||||

Terry Cloth | ||||||||

Wool/Acrylic |

Work Glove Cuff Styles

There are various glove cuff styles to protect and support your wrists while working. For your safety and your ease of use, it's important to consider if the cuff on your glove is designed for the task you are working on.

- Safety Cuff: Often found on leather gloves, safety cuffs have a loose fit with a slit on the side to make it easy for users to remove in the case of an emergency.

- Knit Wrist Cuff: Typically found on sting knits, leather, or cotton gloves, knit wrist cuffs provide a firm grip on the wearer's wrist to reduce glove movement and prevent dirt from entering the glove.

- Gauntlet Cuff: Often found on leather gloves, gauntlet cuffs have a loose fit to allow airflow into the glove. They are longer than safety cuffs, providing additional wrist and forearm protection.

- Slip-On Cuff: Found on leather gloves or jersey-lined gloves, slip-on cuffs feature a seamless design between glove and cuff. This allows the glove to be quickly and easily removed in the case of an emergency.

- Hook and Loop Cuff: Ideal for landscaping jobs, hook and loop cuffs allow you to tighten the cuff on your wrist to prevent dirt from entering the glove.

- Band Top Cuff: Typically found on cotton canvas gloves, band top cuffs protect the wrist while providing ventilation and quick removal.

Work Glove Protection and CE Standard EN 388

To determine if the glove you purchase will provide the industry standard of protection against abrasions, cuts, tears, and punctures, and to determine the difference between the different levels of protection, the CE Standard EN 388 provides a ranking system. The CE mark rates four types of threats to determine how protective the glove may be against the threat. The four types of threats and their tests are:

- The Abrasion Test: 180 grit sandpaper is rubbed in a circular motion over the surface of the glove, and the number of cycles taken to break through the material determines the ranking on a scale of 1 - 4.

- The Cut Test: A circular blade rotates forward and backward over the material, and a ranking on a scale of 1 - 5 is determined based on the number of strokes taken across the fabric. An additional test may be given if the material scores above a ranking of 3, in which a straight blade is run along the fabric. This rating system is ranked on a letter system, from A - F.

- The Tear Test: A tensometer machine pulls a sample of the material apart, providing a rating on a scale of 1 - 4 to determine how much force was required before the material tore apart.

- The Puncture Test: A rounded stylus is forced through the glove material at a regulated speed. The amount of force taken to break through the fabric determines the rating on a scale of 1 - 4.

The higher the score on any test, the more protective the glove is. A glove will show its rating as a series of the four numbers; for example, if a glove showed a CE rating of 3542, it would have gotten a rating of 3 on the abrasion test, 5 on the cut test, 4 on the tear test, and 2 on the puncture test. To ensure your glove is fitting the safety standards needed for your daily tasks, be sure to pay close attention to the CE ratings, as well as any ANSI level information.

Related Resources

Best Disposable Gloves

Compare your disposable glove reviews to identify the gloves that best fit your business needs. Whether you're preparing food, sanitizing surfaces, or handling sensitive materials, disposable gloves are an essential product to have on hand in your workplace. These gloves come in a wide range of styles including general-purpose gloves, heavy-duty gloves, and medical-grade gloves, ensuring that you'll find the glove that matches your business type. They come in a wide range of sizes, making it easy to provide employees with gloves that fit their hands.

Gloves Reviews

Find the best leather gloves, kitchen gloves, and disposable gloves for your business with our wholesale gloves reviews. We make it easy for you to choose the perfect gloves by breaking down the benefits of different styles of work gloves. Compare gloves sizes, glove materials, and application so you can provide your staff with the best hand protection available.

Disposable Gloves FAQ

Disposable gloves are an essential part of foodservice operations, providing a barrier between food and hands to prevent cross-contamination . Questions and concerns often arise when it comes to choosing and using disposable gloves in the foodservice industry. We answer some of the most common questions to help you make informed decisions for your business. Shop All Disposable Gloves Disposable Glove Basics Learn more about the different types of disposable gloves and how to choose the right pair. What Are Disposable Gloves Made Of? Disposable gloves can be made from materials such as latex, vinyl, and nitrile. Each material offers different benefits and drawbacks. Latex gloves are known for their elasticity and comfort, but they can cause

- Topics 1356

- Industrial 55

- Troubleshooting Guides 21

- Restaurant Management 128

- Bar Management 56

- Catering Tips 36

- Bakery Management 42

- Food Trucks & Concessions 49

- Advertising & Marketing 37

- Eco-Friendly Tips 11

- Facility Layout & Design 42

- Coffee Shop Tips 28

- Installation & Maintenance 51

- Janitorial & Pest Control 30

- Safety & Sanitation 88

- Startup Tips 104

- Menu Design 10

- Kitchen & Cooking Tips 83

- Hospitality Management 24

- Pizza & Sandwich Shop Tips 36

- Smallwares 37

- Food Prep 89

- Tabletop Items 17

- Disposables 22

- Calculators & Tools 6

- Consumables 52

- Warewashing & Laundry 19

- Cooking Equipment 91

- Food Storage & Refrigeration 51

- Beverage Equipment 35

- Office Supplies 6

- Resource Type

- In-Depth Articles272

- Buying Guides298

- How-Tos95

- Product Reviews78