Hoshizaki KM Cubers Training: Part 1 Video

0:00

Hoshizaki KM Cubers are designed to be efficient, sanitary, and easy to maintain. Stainless steel evaporator plates, a rebuildable pump assembly, and a small ice drop zone are just a few of the many benefits to these cubers.

Plus, each Hoshizaki ice machine is designed for minimal cleaning to save you on cost and labor.

Products Related To This Video

Related Videos

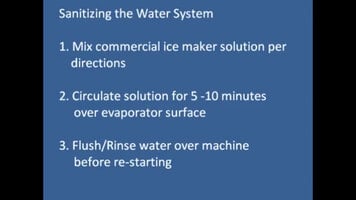

This instructional video gives you insight on how to sanitize the water system in your Hoshizaki KM series ice machine.

Ice is a main ingredient in proper drink making, and thanks to Hoshizaki, you'll always have a dense, perfect ice cube for drinks. Watch this video to learn more about how Hoshizaki ice aids in making wonderfully chilled products every time.

This video shows you how the Hoshizaki KM series ice machine evaporator works to produce individual crescent ice cubes.