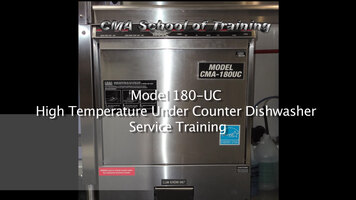

CMA 180UC Undercounter Dishwasher Installation Part 2 Video

0:00

Ensure you have properly installed your CMA 180UC undercounter dishwasher by watching this helpful tutorial!

Products Related To This Video

Related Videos

This instructional video gives you a helpful breakdown of how to properly install your CMA 180UC undercounter dishwasher machine.

Check out this quick video to learn the ins and outs of the CMA 180UC undercounter dishwasher!

Continue your education on CMA 180UC undercounter dishwasher maintenance with this short video. If you want to learn how to maintain components of your machine, this is a great way to become familiar with the inner workings of your dishwasher.