Types of Strip Doors

Shop All Strip Doors

Benefits of Strip Doors

Installing strip doors in your warehouse, commercial kitchen, or other industrial location can both improve working conditions and save you money. Some of the greatest benefits of installing strip doors are highlighted below:

- Separates work environments effectively - When you compare the cost of installing a wall or a traditional door to the cost of putting up a strip door, there's no arguing the fact that strip doors are less expensive, easier to reconfigure and maintain, and will cause less disruption to your business during the initial installation.

- Reduces heating and energy costs - Whether you're attempting to keep cold air inside a walk-in freezer or contain hot, humid air in your dishroom, a strip door creates a barrier that will help insulate rooms. This keeps your heating or refrigeration system from working overtime just to maintain the correct temperature.

- Creates a more comfortable work environment - No one wants to work for a long period of time in conditions that include insects, dust, harsh weather, fumes, or excessive noise. Luckily, strip doors are designed to protect your workers from these undesirable elements and encourage a safer, more comfortable environment.

- Promotes better workflow - It may not seem like much, but every time your employees have to stop to open a traditional door, time is lost. Strip doors not only allow people and equipment to efficiently pass through the door without waiting, but they also increase visibility so your workers can be more aware of their surroundings. This makes for less dangerous working conditions and greater productivity.

Purchasing a Strip Door

- Pre-cut to common door sizes for convenience.

- Mounting bar may be included.

- Replaces individual door plastic strips.

- Cost-effective, comes in pre-cut sizes.

- Create / replace custom-sized plastic strips for doors.

- Rolls 100' - 400' long.

- 2 large strips instead of many small ones.

- Strips swing open and closed.

Strip Door Material and Application

PVC Strip Doors

PVC is the most common material used on curtain door plastic strips. The type of PVC you will want to use is largely dependent on where it's being installed:

- Polar reinforced PVC strip doors are rated for use in freezers or in outdoor applications where temperatures may fall to as low as -40 degrees Fahrenheit.

- Standard grade PVC strip doors are recommended for areas where the ambient temperature will not dip below 0 degrees Fahrenheit.

- Ribbed PVC strip doors are ideal for heavy traffic areas because they significantly reduce the appearance of scratches and mars in the material. This keeps your workers safe by ensuring that their visibility isn't compromised.

Although many strip doors are clear for visibility purposes, there are also tinted versions available for use in specific applications like welding partitions or forklift traffic lanes.

In general, the PVC material used to make strip doors is rated based on the following criteria:

- Thermal Conductivity - The rate at which heat passes through the strip door

- Tensile Strength - The maximum amount of stress the strip door can withstand before stretching, tearing, etc.

- Noise Abatement - The reduction in decibels as a result of the strip door, which often depends on the thickness of the material

- Ultraviolet-Resistance - Some strip doors contain ultraviolet inhibitors to allow them to be used outdoors in direct sunlight

- Anti-Static - Some strip doors are rated for use where static can be dangerous, such as areas that contain flammable substances

- Flame-Resistance - Some strip doors are rated for flame resistance since certain states have more stringent guidelines on the use of flame retardant material

Mesh Strip Doors

Mesh strip doors

are a great option for spaces that just need to control insects, with no temperature regulation. These doors also promote airflow through rooms that need to be aerated due to cooking or cleaning.They're a great option for back doors of restaurants, cafeterias, and food prep facilities, and the strips are weighted on the bottom to prevent them from blowing too freely in a breeze.

Temperature Range | Standard: 0-160 degrees Fahrenheit

Polar Reinforced: -40-140 degrees Fahrenheit | Standard: 0-160 degrees Fahrenheit

Polar Reinforced: -20-150 degrees Fahrenheit | Standard: 0-150 degrees Fahrenheit

Polar Reinforced: -20-140 degrees Fahrenheit | Standard: 0-150 degrees Fahrenheit | N/A | -30-125 degrees Fahrenheit |

Insect Protection | ||||||

Dock Doors | ||||||

Cooler Doors | ||||||

Freezer Doors | ||||||

Spray Areas | ||||||

Restaurant Doors | ||||||

Personnel Doors | ||||||

Light Industrial Doors | ||||||

Medium Industrial Doors | ||||||

Forklift Traffic | ||||||

Temperature Control | ||||||

Workflow Improvement | ||||||

Comfort Control | ||||||

Warehouse Doors |

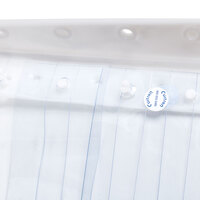

Replacement Plastic Strips for Doors

One of the best things about strip doors is that a tear in one strip doesn't mean the entire door has to be thrown away. However, knowing the difference between the styles of plastic flaps for doors and how they attach to the mounting bar is an important part of your purchasing consideration.

Looped strips feature a heat-sealed loop at the end of each strip. Because this type of strip slides onto a mounting bar rather than attaching to individual hooks, it is less likely to fall off and interrupt the workflow of your business. The mounting bar also makes it easier to clean the door; simply remove the bar to take the door down and clean everything at the same time.

Punched hole strips have several holes at the end of each strip. To hang this type of strip, each hole must be matched up to a hook or peg in order to stay fastened. This design makes individual strips easy to replace or clean, but they are more prone to ripping off in high-traffic locations and can be more tedious to attach.

Customizing Your Strip Door

Perhaps after browsing our selection of strip doors, you've decided that buying a roll of material and creating your own customized strip door is the best option for you. Follow these steps to create a tailor-made strip door without the fear of wasting material!

1. Measure your door opening.

In addition to recording the dimensions of the doorway, it's important to note anything that may hinder the installation of the door like space limitations on either side of the door or obstructions within the door frame.

2. Determine how wide the strips need to be.

Consider what type of traffic will be moving through the door. For personnel, carts, and general traffic, 6"-8" wide strips will work fine. Larger equipment and industrial-type traffic should use 12"-16" wide strips. Check out the chart below for some guidelines on choosing the right width.

Door Height |

Exterior Door/Heavy Traffic |

Interior Door/Light Traffic |

||

|---|---|---|---|---|

| Strip Width | Strip Thickness | Strip Width | Strip Thickness | |

7' |

4"-6" |

.060" |

||

8' |

8" |

.080" |

||

10' |

8" |

.080" |

||

12' |

12" |

.120" |

||

14' |

12" |

.120" |

||

16' |

16" |

.160" |

||

18' |

16" |

.160" |

||

3. Decide how much overlap you want between strips.

If you're installing an exterior door, it's best to go with 100% overlap to protect against inclement weather and wind. Indoor applications can generally get away with 25%, 50%, or 75% overlap.

4. Determine the linear footage of PVC strip needed for your application.

Find the strip width you chose on the chart below, and cross reference against the percentage of overlap you want to get the "multiplying factor."

Multiplying Factors |

||||

|---|---|---|---|---|

Strip Width |

25% |

50% |

75% |

100% |

4" |

4 |

6 |

||

6" |

4 |

|||

8" |

1.75 |

2 |

2.5 |

3 |

12" |

1.35 |

2 |

||

16" |

.875 |

1 |

1.2 |

1.5 |

Then, follow these instructions to determine the amount of material you will need to create your custom strip door. This calculation gives you the answer in linear footage so you know how long of a roll you should buy to complete your project. In the example below, you would need a roll at least 104' long to create a strip door to cover your door opening.

Instructions |

Multiply the door width (') by the multiplying factor you found in the table above. |

Add 1 to get the total number of strips you need (adding an additional strip accounts for edge exposure). |

Multiply the total number of strips by your door height (') to get the total linear footage of PVC strip needed. |

Example (4'W x 8'H door with 8" strips and 100% overlap) |

4' x 3 = 12 |

12 + 1 = 13 |

13 x 8' = 104' |

5. Identify the best strip material for your application.

The type of strip you need to purchase is entirely dependent on where you will place the strip door. For example, if you're installing the door into a freezer, you will need to purchase a low temperature strip. If visibility is important because you're placing it in a high traffic area, then a standard, clear PVC strip is the perfect choice.

6. Consider how you will mount the strip door.

There are a variety of ways that you can mount your strip door, and while the most common ways are wall or in-jamb mounts, there are others to consider listed in the chart below!

Type of Mount | Explanation | Best Application | Potential Drawbacks |

|---|---|---|---|

In-Jamb Mount | Hardware that is mounted within the doorframe | Doors where space immediately around the doorframe is limited | Lowers the height of the door |

Wall Mount | Hardware that is mounted above the door | Good for the majority of applications | Requires more strip material to cover the same door opening |

Universal Mount | Hardware that can be mounted within or above the doorframe | When a large number of strip doors are ordered with varying mounting requirements or there is uncertainty over which mounting option will work best | Can affect the amount of strip material needed to cover the entire door, depending on which mounting option is used |

Piano Hinge | Hinge that allows the entire door to pivot | Doors that need to accommodate two-way traffic or large equipment with little clearance room | Lowers the height of the door |

Overhead Door Bracket | Brackets that allow the door to be mounted away from the door opening | Doorways that contain an obstruction like a door track or a pipe | Takes up more space around the door as the brackets project from the wall around the doorway |

Sliding Track | Track that allows the strip door to be slid completely out of the way without taking it down | Doorways where the strip door is not always necessary due to climate or application | Must be ample room on one or both sides of the door to use this type of mount |

Accordion Hardware | Hardware that works similar to a sliding track but can be mounted within the doorframe when there is not enough space on either side of the door to mount a sliding track | Doorways where there is not enough space to allow for a sliding strip door; doorways where the strip door is not always necessary due to climate or application | Can limit the amount of space within the doorframe |

Related Resources

How to Ship Food

Shipping food presents a unique challenge, requiring the proper containers and procedures to ensure the food arrives in good condition. From appropriate packaging to temperature control methods, various factors impact your food's quality when it reaches its destination. In addition to explaining how to ship food, we describe what shipping supplies you'll need, how to use dry ice, and answer common questions so you can ship food with minimal issues. Shop All Shipping Supplies Use the following links to learn how to ship food: How to Ship Frozen Food How to Ship Refrigerated Items How to Ship Meat Shipping with Dry Ice How to Ship Dried Food Types of Food Shipping Containers Types of Coolants Shipping Food FAQ

Pest Control Products Guide

Controlling and eliminating pests is important for all businesses, but it is especially critical in the food service and hospitality industries . The presence of pests is an indicator of uncleanliness and poor hygiene, which will damage your business's reputation. Pests also carry harmful diseases and bacteria that can harm staff and customers, meaning it's vital you take the proper preventative measures to keep your business pest-free . Protect your business with a variety of pest control products, allowing you to combat the threat pests pose to your establishment and even prevent infestations before they can even start. Shop All Pest Control Products Use the following links to Iearn more about different types of pest control products: Rod

Food Safety Guidelines

Food safety guidelines are put in place to keep customers safe and prevent the risk of a foodborne illness outbreak. Any operation that serves food should establish protocols that meet the legal requirements for safe food handling. In this guide, we'll outline the most important aspects of food safety to help you build an effective program for your business and pass your next health inspection . Click below to learn about important food safety programs: Personal Hygiene Proper Food Handling Cleaning and Sanitizing Pest Control Purchase from Approved Suppliers Food Safety Training Food Safety Guidelines for Restaurants We'll cover the most important aspects of a successful food safety program so you can prevent a foodborne illness outbreak a

- Topics 1344

- Industrial 55

- Troubleshooting Guides 21

- Restaurant Management 128

- Bar Management 55

- Catering Tips 35

- Bakery Management 41

- Food Trucks & Concessions 49

- Advertising & Marketing 37

- Eco-Friendly Tips 11

- Facility Layout & Design 41

- Coffee Shop Tips 27

- Installation & Maintenance 51

- Janitorial & Pest Control 30

- Safety & Sanitation 88

- Startup Tips 104

- Menu Design 10

- Kitchen & Cooking Tips 81

- Hospitality Management 23

- Pizza & Sandwich Shop Tips 36

- Smallwares 37

- Food Prep 88

- Tabletop Items 17

- Disposables 22

- Calculators & Tools 6

- Consumables 52

- Warewashing & Laundry 18

- Cooking Equipment 90

- Food Storage & Refrigeration 51

- Beverage Equipment 34

- Office Supplies 6

- Resource Type

- In-Depth Articles272

- Buying Guides296

- How-Tos93

- Product Reviews77